A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

FERC RM22-12-000; ORDER NO. 901 Explained: Engineering, Modeling, and Compliance Implications for the Bulk Power System

february 1, 2026 | Blog

Introduction

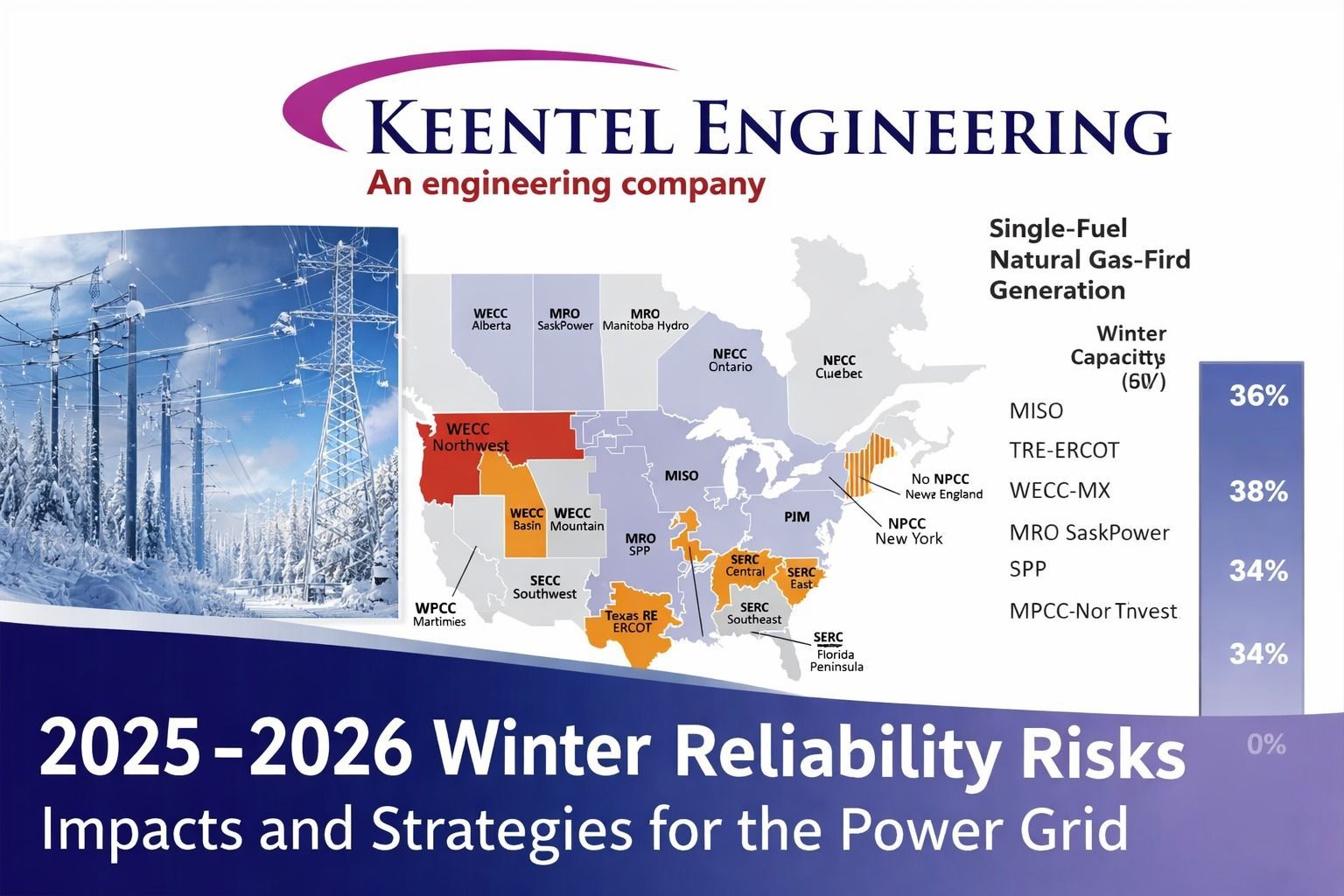

The reliability of the Bulk Power System (BPS) increasingly depends on the accuracy, transparency, and technical rigor of power system models used for planning and operational studies. Over the last decade, the North American grid has experienced a fundamental transformation driven by inverter-based resources (IBRs), large-scale renewables, distributed energy resources, and increasingly complex control systems. As system behavior becomes more dynamic and less predictable, long-standing assumptions embedded in steady-state and transient stability models are no longer sufficient.

Recognizing these challenges, the Federal Energy Regulatory Commission (FERC) issued RM22-12-000; ORDER NO. 901, a rulemaking proceeding focused on improving the quality, availability, and validation of power system modeling data used to support reliability assessments. This action signals a clear shift in regulatory expectations: model accuracy is no longer optional, and engineering rigor must match the complexity of the modern grid.

For Generator Owners (GOs), Transmission Owners (TOs), Planning Coordinators (PCs), and Resource Entities, RM22-12-000; ORDER NO. 901 has far-reaching implications. It affects how models are developed, validated, submitted, maintained, and audited. It also places increased responsibility on engineering firms to provide technically defensible studies that withstand regulatory scrutiny.

This article explains RM22-12-000; ORDER NO. 901 from an engineering and compliance execution perspective, highlighting what stakeholders must do, where industry gaps exist, and how firms like Keentel Engineering support clients in meeting these evolving expectations.

Regulatory Background and Industry Context

FERC’s authority under the Federal Power Act includes ensuring the reliability of the interstate transmission system. Historically, this responsibility has been delegated to the North American Electric Reliability Corporation (NERC), which develops and enforces reliability standards subject to FERC approval. While NERC standards such as MOD, TPL, and PRC govern modeling, planning, and protection practices, FERC has increasingly expressed concern that existing standards alone are insufficient to address emerging grid risks.

Several high-profile disturbance events involving inverter-based resources exposed deficiencies in:

- Dynamic model fidelity

- Control representation

- Model validation practices

- Data sharing between entities

Investigations repeatedly identified inaccurate or incomplete models as contributing factors. RM22-12-000; ORDER NO. 901 responds directly to these findings by emphasizing data quality, transparency, and accountability across the modeling lifecycle.

Why FERC Issued RM22-12-000; ORDER NO. 901

At its core, RM22-12-000; ORDER NO. 901 addresses a simple but critical question:

How can the industry ensure that reliability studies reflect how the grid actually behaves?

FERC identified several systemic issues:

- Generator models not reflecting as-built controls

- Inconsistent modeling practices across regions

- Limited validation using field measurements

- Delayed updates following plant modifications

- Insufficient visibility into third-party or proprietary models

As inverter-based generation grows, these issues introduce unacceptable risk. Unlike synchronous machines, IBRs rely on complex control algorithms that can interact in unexpected ways during disturbances. Small modeling errors can cascade into widespread reliability impacts.

RM22-12-000; ORDER NO. 901 establishes the expectation that:

- Models must be accurate, current, and validated

- Data must be accessible to planners and operators

- Engineering assumptions must be technically justified

Relationship to NERC Reliability Standards

RM22-12-000; ORDER NO. 901 does not replace NERC standards; instead, it raises the bar for how they are implemented.

Key affected standards include:

- MOD-026 / MOD-027 – Generator excitation and governor modeling

- MOD-032 / MOD-033 – Data provision and verification

- TPL-001 – Transmission system planning

- PRC-019 / PRC-024 – Protection system coordination

- PRC-029 – Frequency and voltage ride-through for IBRs

FERC’s message is clear: compliance is not just about checking boxes. Entities must demonstrate that their engineering work produces reliable results.

Impact on Generator Owners and Developers

For Generator Owners, RM22-12-000; ORDER NO. 901 significantly expands modeling responsibilities. Developers can no longer rely solely on vendor-supplied “standard” models without verification.

Key expectations now include:

- Submission of site-specific dynamic models

- Validation against commissioning or operational data

- Timely updates following plant changes

- Coordination with Planning Coordinators and ISOs

Failure to meet these expectations increases exposure to:

- Study rejection

- Interconnection delays

- Compliance findings

- Retrofit or mitigation costs

Implications for Inverter-Based Resources (IBRs)

IBRs are central to RM22-12-000; ORDER NO. 901. Their fast control response, non-linear behavior, and dependency on software logic require higher-fidelity modeling approaches.

Engineering challenges include:

- EMT vs RMS model selection

- Representation of plant-level controllers

- Modeling protection and limiters

- Capturing weak-grid interactions

FERC’s direction strongly implies greater reliance on:

- EMT studies for disturbance analysis

- Hardware-in-the-loop (HIL) validation

- Cross-platform model consistency

Modeling Accuracy and Validation Expectations

RM22-12-000; ORDER NO. 901 elevates model validation from a best practice to a regulatory expectation.

Validation methods may include:

- Playback of disturbance recordings

- Comparison with commissioning test data

- Parameter tuning using operational measurements

- Cross-verification between software tools

Engineering firms must now document:

- Assumptions

- Data sources

- Model limitations

- Validation results

ISO/RTO-Specific Considerations

Each ISO/RTO implements RM22-12-000; ORDER NO. 901 principles differently:

- ERCOT emphasizes TSAT and EMT modeling for IBRs

- PJM requires strict adherence to dynamic model guidelines

- CAISO mandates detailed inverter modeling and validation

- SPP and MISO are expanding EMT study requirements

- WECC continues to lead in high-fidelity modeling expectations

Understanding regional nuances is critical for compliance.

Common Industry Gaps Identified by FERC

Typical deficiencies include:

- Outdated models

- Incorrect control settings

- Missing protection logic

- Incomplete documentation

- Poor coordination between owners and planners

These gaps are increasingly cited in audits and disturbance investigations.

Engineering Best Practices for RM22-12-000; ORDER NO. 901 Compliance

Best practices include:

- Treating models as living assets

- Implementing change management procedures

- Using multiple simulation platforms

- Performing periodic model audits

- Maintaining traceable documentation

How Keentel Engineering Supports RM22-12-000; ORDER NO. 901 Compliance

Keentel Engineering provides end-to-end support, including:

- High-fidelity RMS and EMT modeling

- Model validation and benchmarking

- ISO/RTO study support

- NERC compliance documentation

- Independent technical reviews

Keentel bridges the gap between regulatory intent and engineering execution, ensuring clients remain compliant while minimizing project risk.

Frequently Asked Questions (FAQs)

1. What is FERC RM22-12-000; ORDER NO. 901?

RM22-12-000; ORDER NO. 901 is a FERC rulemaking focused on improving the accuracy, availability, and validation of power system modeling data used for reliability studies.

2. Who is affected by RM22-12-000; ORDER NO. 901?

Generator Owners, Transmission Owners, Planning Coordinators, ISOs/RTOs, and engineering firms involved in modeling and studies.

3. Does RM22-12-000; ORDER NO. 901 create new NERC standards?

No, but it influences how existing standards are interpreted and enforced.

4. Why is model accuracy so important?

Inaccurate models can lead to incorrect study results, hidden reliability risks, and real-world system failures.

5. Are inverter-based resources the main focus?

Yes. IBRs present unique modeling challenges that drove this rulemaking.

6. Does RM22-12-000; ORDER NO. 901 require EMT studies?

While not explicitly mandated, it strongly supports expanded EMT analysis where RMS models are insufficient.

7. What happens if submitted models are inaccurate?

Entities may face study rejection, mitigation requirements, or compliance findings.

8. How often must models be updated?

Models should be updated whenever material changes occur and periodically validated.

9. Are vendor models sufficient?

Not without site-specific validation and tuning.

10. How does this affect interconnection studies?

Poor modeling can delay approvals and trigger restudies.

11. What documentation is expected?

Assumptions, validation methods, test results, and model limitations.

12. How does RM22-12-000; ORDER NO. 901 relate to PRC-029?

Both address inverter behavior during disturbances, emphasizing accurate representation.

13. Are legacy generators affected?

Yes, especially if models no longer reflect actual equipment.

14. What role do engineering firms play?

They provide independent verification, modeling expertise, and compliance support.

15. How does Keentel Engineering help?

Keentel delivers validated models, defensible studies, and audit-ready documentation.

16. Is data sharing required?

Yes, to the extent necessary for planners to perform reliable studies.

17. How does this affect weak grid studies?

It increases scrutiny on voltage and frequency stability modeling.

18. What are common audit findings?

Outdated models, missing validation, undocumented assumptions.

19. Are software tools regulated?

No, but their proper use and limitations must be understood.

20. Can EMT replace RMS studies?

No. They are complementary tools.

21. Does this apply to BESS?

Yes, battery systems are a major focus.

22. How should owners prepare?

Audit existing models, validate data, and engage qualified engineers.

23. What is the biggest risk of non-compliance?

Hidden reliability risks that surface during disturbances or audits.

24. Is RM22-12-000; ORDER NO. 901 a one-time effort?

No. It establishes ongoing expectations.

25. Why choose Keentel Engineering?

Because compliance requires engineering depth, not just regulatory knowledge.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.