A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

| Category | Metric |

|---|---|

| VPP capacity (Lunar Energy) | 650 MW |

| Lunar funding raised | US$232 million |

| Data center BESS example | 31 MW / 62 MWh |

| ERCOT grid-scale batteries | 15+ GW |

| LDES tenders (H1 2026) | Up to 9.3 GW |

| Lithium-ion share of LDES by 2030 | 77% |

| FEOC initial threshold | 55% |

| BESS tariff rate (2026) | ~55% |

| Capacity gain from analytics | 5–15% |

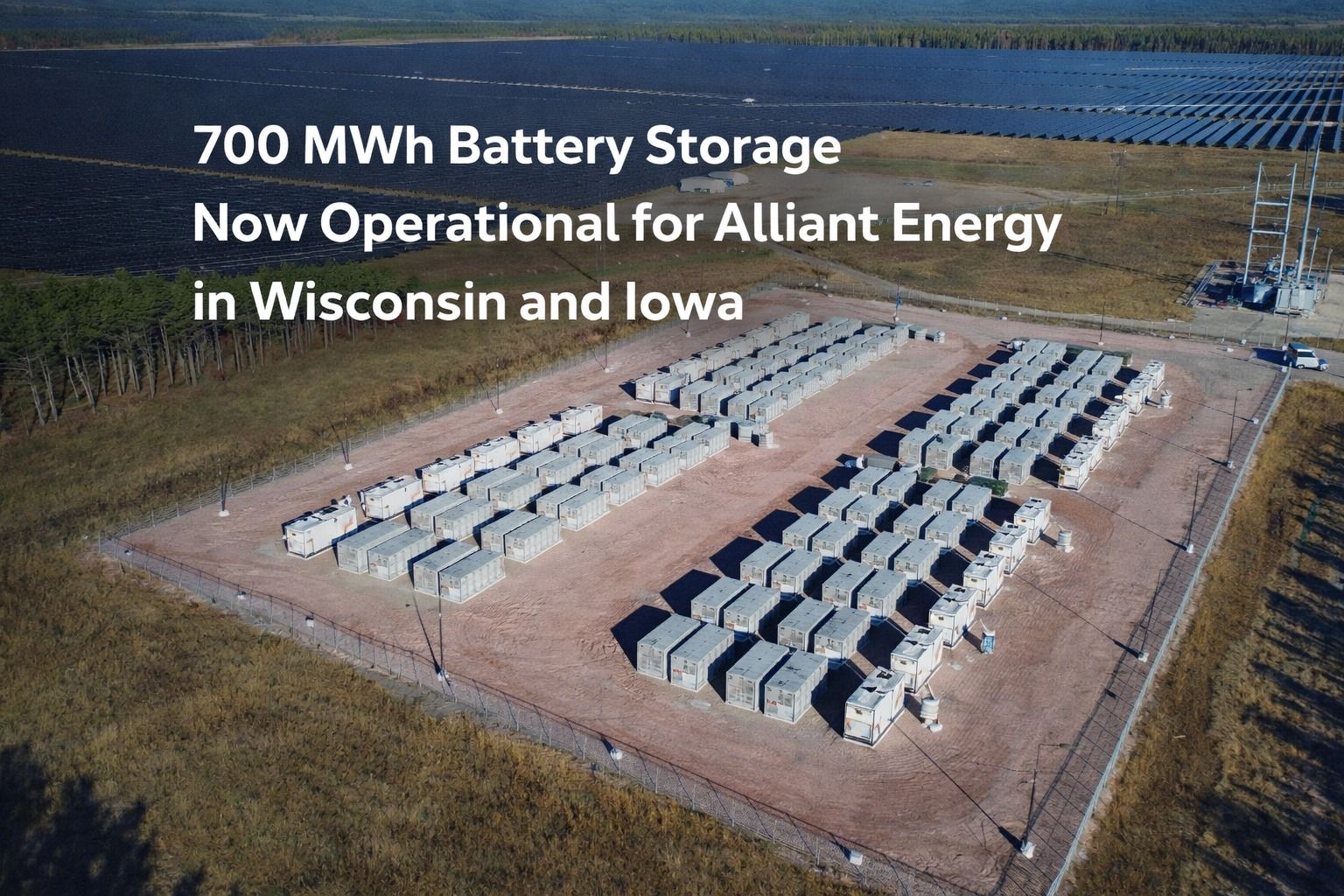

Utility-Scale Battery Energy Storage Reaches a New Operating Benchmark: Statistical Insights from Alliant Energy’s 700 MWh Deployment in the Midwest

February 10, 2026 | Blog

Executive Overview

Utility-scale battery energy storage systems (BESS) in the United States are transitioning from pilot deployments to system-critical infrastructure. In early 2026, FlexGen placed 700 MWh of grid-scale battery storage into commercial operation for Alliant Energy across Wisconsin and Iowa, representing one of the largest coordinated utility BESS deployments in the Midwest to date.

The projects illustrate how utilities are increasingly using storage to:

- Firm large-scale solar generation

- Defer traditional grid infrastructure upgrades

- Improve operational flexibility under rising load growth

- Support long-term decarbonization targets

This article examines the technical scale, statistical context, grid planning implications, and software integration trends associated with Alliant Energy’s expanding BESS portfolio.

1. Project Scale and Technical Configuration

FlexGen designed, built, and integrated two major BESS facilities for Alliant Energy:

Wisconsin – Wood County BESS

- Capacity: 75 MW / 300 MWh

- Location: Saratoga, Wisconsin

- Co-located with: 150 MW solar PV facility

- Duration: 4 hours

- Status: Operational (2026)

This project brings Alliant Energy’s planned and operational energy storage capacity in Wisconsin to 275 MW, marking a substantial increase in the state’s utility-scale storage footprint.

Iowa – Wever BESS

- Capacity: 100 MW / 400 MWh

- Location: Southeast Iowa

- Co-located with: 150 MW solar PV facility

- Duration: 4 hours

- Status: Operational (2026)

With three additional projects under development, Alliant Energy’s total planned battery storage capacity in Iowa is expected to reach approximately 400 MW.

Aggregate Statistics

| Metric | Value |

|---|---|

| Total BESS capacity | 175 MW / 700 MWh |

| Average duration | 4 hours |

| Solar capacity supported | 300 MW |

| States served | Wisconsin, Iowa |

| Monitoring | 24/7 utility operations |

2. Statistical Context: Storage as a Grid Planning Tool

The Alliant Energy projects align with broader statistical trends observed across North America:

- 4-hour duration systems remain the dominant configuration for utility-scale deployments, balancing cost, operational flexibility, and market participation

- Co-location with solar reduces:

- Curtailment risk

- Peak transmission congestion

- Interconnection upgrade requirements

- Storage increasingly replaces or defers:

- New distribution lines

- Substation upgrades

- Peaking generation capacity

Alliant Energy explicitly noted that these BESS projects help avoid customer costs associated with traditional equipment replacement or construction of new lines and poles—a critical economic driver as electricity demand rises.

3. Operational Reliability and Safety Engineering

Both the Wood County and Wever BESS facilities are:

- Monitored continuously (24/7)

- Integrated into utility operational workflows

- Connected to rapid response protocols for performance deviations

In addition, Alliant Energy:

- Coordinated with local fire departments

- Conducted joint safety planning and emergency response preparation

- Implemented operational readiness procedures prior to commercial operation

This reflects a broader industry shift toward standardized BESS safety coordination between utilities, integrators, and first responders.

4. Software Integration as a Core System Layer

FlexGen provided full system integration using its HybridOS energy management system (EMS), which plays a central role in modern utility-scale storage deployments.

Key EMS Functions

- Real-time dispatch optimization

- State-of-charge (SoC) management

- Asset health monitoring

- Market participation and scheduling

- Grid services coordination

As BESS fleets scale from tens to hundreds of megawatt-hours, software increasingly determines asset value, availability, and revenue performance.

5. Market Consolidation and Platform Continuity

FlexGen’s role in these projects follows its 2025 acquisition of key assets from Powin, approved by the U.S. Bankruptcy Court.

As part of that transaction:

- FlexGen acquired Powin’s intellectual property, including hardware and software platforms

- Powin’s fielded projects were transitioned to FlexGen’s Remote Operations Center (ROC)

- HybridOS controls software was extended to existing Powin customers

- Spare parts inventories and IT systems were absorbed

This consolidation highlights a broader market trend:

Utilities increasingly value integrators with long-term software, controls, and lifecycle support capabilities over standalone hardware providers.

6. Alliant Energy’s Long-Term Decarbonization Strategy

The BESS deployments support Alliant Energy’s published environmental targets:

| Target | Year |

|---|---|

| 50% reduction in GHG emissions (vs. 2005) | 2030 |

| Full coal phase-out | 2040 |

| Net-zero utility operations | 2050 |

Energy storage serves as a critical enabling technology, allowing

renewable generation

to displace fossil resources while maintaining system reliability.

7. Engineering Implications for Utilities and System Planners

The Alliant–FlexGen projects reinforce several engineering conclusions:

- Storage is now core grid infrastructure, not a supplemental asset

- Co-located BESS reduces total system costs more effectively than standalone grid upgrades

- EMS and controls architecture must scale with fleet size

- Operational readiness and safety coordination are non-negotiable design inputs

- Storage enables decarbonization without sacrificing reliability

Key Statistics at a Glance

| Category | Statistic |

|---|---|

| Total BESS deployed | 700 MWh |

| Largest single project | 100 MW / 400 MWh |

| Average system duration | 4 hours |

| Solar supported | 300 MW |

| States impacted | 2 |

| Utility decarbonization horizon | 2050 |

Frequently Asked Questions (FAQs)

Why are utilities deploying 4-hour BESS systems?

Four-hour systems balance cost and operational flexibility, supporting peak shaving, renewable firming, and grid services without the higher capital cost of longer durations.

How does co-location reduce grid costs?

Co-located BESS can use existing interconnections, reduce congestion, and defer transmission and distribution upgrades.

Why is EMS software critical?

As fleets scale, manual dispatch is infeasible. EMS platforms optimize performance, ensure safety, and unlock multiple revenue and reliability services.

How does storage support decarbonization?

BESS allows higher renewable penetration by smoothing intermittency and reducing reliance on fossil peaking resources.

Is market consolidation a risk or benefit?

For utilities, consolidation can improve long-term support, software continuity, and system standardization—if managed properly.

Closing Perspective

The commissioning of 700 MWh of utility-scale battery storage for Alliant Energy reflects a decisive shift in how U.S. utilities plan, operate, and modernize the grid. Storage is no longer experimental—it is a statistically material, operationally essential asset class.

As load growth accelerates and decarbonization targets tighten, projects like these demonstrate how engineering-driven storage deployment can deliver reliability, flexibility, and long-term cost control simultaneously.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.