A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

PRC-030-1 Event Analysis and Corrective Actions for Inverter-Based Resources (IBRs) - Keentel Engineering

December 25, 2025 | Blog

A Practical Guide for Generator Owners Navigating Post-Disturbance Compliance

Introduction: Why PRC-030-1 Matters Now

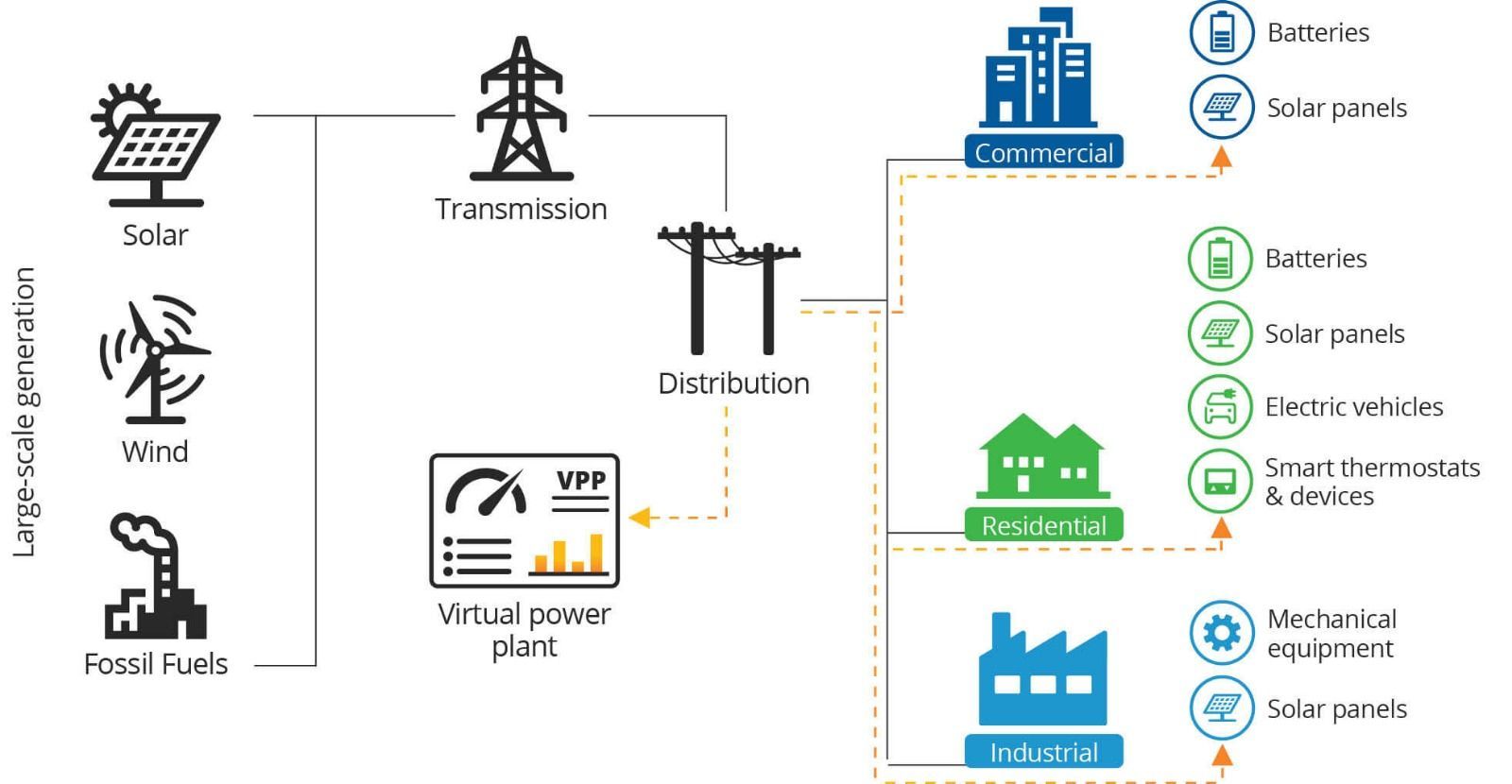

The North American Bulk Power System is undergoing one of the most significant transitions in its history. Inverter-Based Resources (IBRs) including utility-scale solar, wind, and battery energy storage systems are rapidly replacing conventional synchronous generation. While these technologies provide clear operational and environmental benefits, they also introduce new reliability risks, particularly during and following grid disturbance events.

To address these emerging challenges, the North American Electric Reliability Corporation (NERC) introduced PRC-030-1 – Unexpected Inverter-Based Resource Event Mitigation, a reliability standard focused on post-disturbance performance. While much industry attention has historically been placed on real-time IBR behavior—such as voltage and frequency ride-through—PRC-030-1 recognizes that post-event analysis and corrective actions are equally critical to maintaining long-term grid reliability.

For Generator Owners (GOs), PRC-030-1 represents a fundamental shift in compliance expectations. IBR disturbance events can no longer be treated as isolated operational anomalies. Instead, they must be systematically identified, engineering-analyzed, and mitigated using documented, repeatable, and auditable processes.

This guide provides an engineering-focused breakdown of PRC-030-1, explains how it fits within the broader NERC protection and control framework, and outlines practical steps Generator Owners should take to prepare for post-disturbance compliance obligations.

Regulatory Background and Implementation Timeline

PRC-030-1 was adopted by the NERC Board of Trustees on October 8, 2024, following extensive industry engagement and technical justification. The standard was subsequently approved by FERC on February 20, 2025, reflecting regulatory concern over widespread and coordinated IBR performance issues observed in recent disturbance events.

The standard includes phased implementation timelines:

- Bulk Electric System (BES) IBR facilities: Effective October 1, 2026

- Non-BES IBR facilities (≥20 MVA, ≥60 kV): Effective January 1, 2027, or the standard’s effective date, whichever is later

Once enforceable, PRC-030-1 becomes subject to mandatory compliance audits, spot checks, and self-certifications, with violation severity levels that escalate based on timeliness, completeness, and effectiveness of event analysis and mitigation actions.

See our NERC Compliance Services.

How PRC-030-1 Fits with PRC-029-1

PRC-029-1 and PRC-030-1 are best understood as complementary standards:

- PRC-029-1 defines how IBRs must perform during grid disturbances, including voltage and frequency ride-through expectations. (Ensuring NERC PRC-029-1 Compliance for IBRs)

- PRC-030-1 governs what Generator Owners must do after a disturbance when unexpected or unacceptable IBR behavior occurs.

Together, they form a closed-loop reliability framework:

- Before the event: Design, modeling, and settings compliance

- During the event: Ride-through and dynamic performance

- After the event: Analysis, corrective actions, and mitigation

This lifecycle-based approach reflects NERC’s growing expectation that Generator Owners actively manage IBR risk—not only through design, but through continuous operational learning and improvement.

Overview of PRC-030-1 Requirements

PRC-030-1 consists of four requirements (R1–R4) that establish a structured, event-driven compliance process.

At a high level, Generator Owners must:

- Identify qualifying IBR events

- Analyze IBR performance during those events

- Develop corrective actions or technical justifications

- Implement corrective actions and track completion

Each requirement builds on the previous one, creating a defensible chain of evidence from disturbance detection through mitigation.

Requirement R1: Event Identification and Detection

What Triggers PRC-030-1?

PRC-030-1 applies when an IBR facility experiences either:

- A complete loss of output, or

- A change in real power output of at least 20 MW and at least 10% of the plant’s gross nameplate rating,

- Occurring within a four-second window

This dual threshold ensures that PRC-030-1 captures events that are both material in size and sudden in nature, which are more likely to indicate control, protection, or coordination issues.

Exclusions Matter

The standard explicitly excludes:

- Variability due to wind speed or solar irradiance

- Planned dispatch, ramping, outages, or testing

- Collection or transmission system losses that inherently disconnect the plant

- Power reductions caused solely by Protection System Misoperations addressed under PRC-004

These exclusions are critical. Generator Owners must be able to demonstrate why an event was excluded, not simply assert that it does not apply.

Engineering Implications

To comply with R1, Generator Owners need:

- High-resolution MW data (sub-second where possible)

- Automated event detection logic

- Documented screening criteria

- Evidence that the detection process is consistently implemented

Many organizations underestimate this step. If you miss the event, everything downstream fails.

Requirement R2: Event Analysis and Performance Assessment

The 90-Day Clock

Once a qualifying event is identified—or when requested by a Reliability Coordinator, Balancing Authority, or Transmission Operator—the Generator Owner has 90 calendar days to complete a comprehensive analysis.

Required Elements of the Analysis

R2 mandates that the analysis include:

1. Root Cause Determination

This may involve:

- Inverter control logic

- Protection settings

- Plant controller behavior

- Communication delays or failures

- Firmware or configuration issues

- Grid condition interactions

A simple “equipment malfunction” explanation is not sufficient. NERC expects engineering rigor and traceability.

2. Ride-Through and Reactive Power Performance

Generator Owners must document:

- Voltage and frequency response

- Momentary cessation behavior

- Reactive current injection or absorption

- Compliance with interconnection requirements

This requirement closely aligns PRC-030-1 with PRC-029-1 and dynamic modeling obligations.

3. Performance Issue Assessment

The analysis must explicitly state whether:

- The observed behavior represents a performance deficiency

- Corrective actions are required to prevent recurrence

4. Fleet-Wide Applicability

Perhaps the most overlooked requirement:

Generator Owners must assess whether the root cause could apply to other IBR facilities they own.

This shifts PRC-030-1 from a site-specific standard to a portfolio-level reliability obligation.

Requirement R3: Corrective Action Plans or Technical Justifications

CAP or Justification—But Not Silence

If the R2 analysis identifies performance issues, Generator Owners must, within 60 calendar days, either:

- Develop a Corrective Action Plan (CAP), or

- Provide a technical justification explaining why corrective action is not required

Both must be provided to the associated RC, BA, and TOP.

What Makes a Defensible CAP?

A strong CAP includes:

- Clear problem statements

- Defined corrective actions

- Responsible parties

- Implementation timelines

- Verification methods

Examples of corrective actions may include:

- Inverter firmware updates

- Control logic modifications

- Protection setting changes

- Plant controller coordination updates

- Operating procedure revisions

CAPs must also address other applicable facilities, not just the affected plant.

Requirement R4: Implementation and CAP Management

PRC-030-1 does not stop at planning. Generator Owners must:

- Implement the CAP

- Update it if timelines or actions change

- Notify Reliability Coordinators when changes occur

- Document CAP completion

From a compliance perspective, failure to implement a CAP is among the most severe violations under PRC-030-1.

Evidence Retention and Audit Expectations

PRC-030-1 requires Generator Owners to retain evidence for 36 calendar months, including:

- Event detection procedures

- Event data and recordings

- Analysis reports

- CAPs and technical justifications

- Implementation records and communications

Auditors will expect:

- Traceability from event detection to mitigation

- Engineering depth

- Consistency across facilities

- Clear timelines

Common Pitfalls We See at Keentel Engineering

Through industry experience, several recurring challenges stand out:

- Treating PRC-030-1 as a paperwork exercise rather than an engineering process

- Lack of high-resolution data

- Inadequate root cause analysis

- Failure to assess fleet-wide applicability

- Poor CAP tracking and change management

PRC-030-1 is not forgiving of superficial analysis.

How Keentel Engineering Supports PRC-030-1 Compliance

At Keentel Engineering, we help Generator Owners navigate PRC-030-1 through:

- Event detection framework development

- Engineering-grade root cause analysis (See our power system studdies services)

- Ride-through and reactive power performance evaluation

- CAP development and implementation support

- Audit-ready documentation and evidence packages

- Integration with PRC-029, PRC-004, and dynamic modeling requirements

Our approach is grounded in power system engineering, not just compliance theory.

Final Thoughts: PRC-030-1 as an Opportunity

PRC-030-1 is more than a compliance obligation—it is an opportunity to:

- Improve IBR performance

- Reduce repeat disturbances

- Strengthen grid reliability

- Protect Generator Owners from regulatory and operational risk

Organizations that invest early in robust post-event analysis processes will be better positioned as inverter-based generation continues to dominate the grid.

If you would like assistance preparing for PRC-030-1 compliance, Keentel Engineering is ready to help.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.