A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

| Category | Metric |

|---|---|

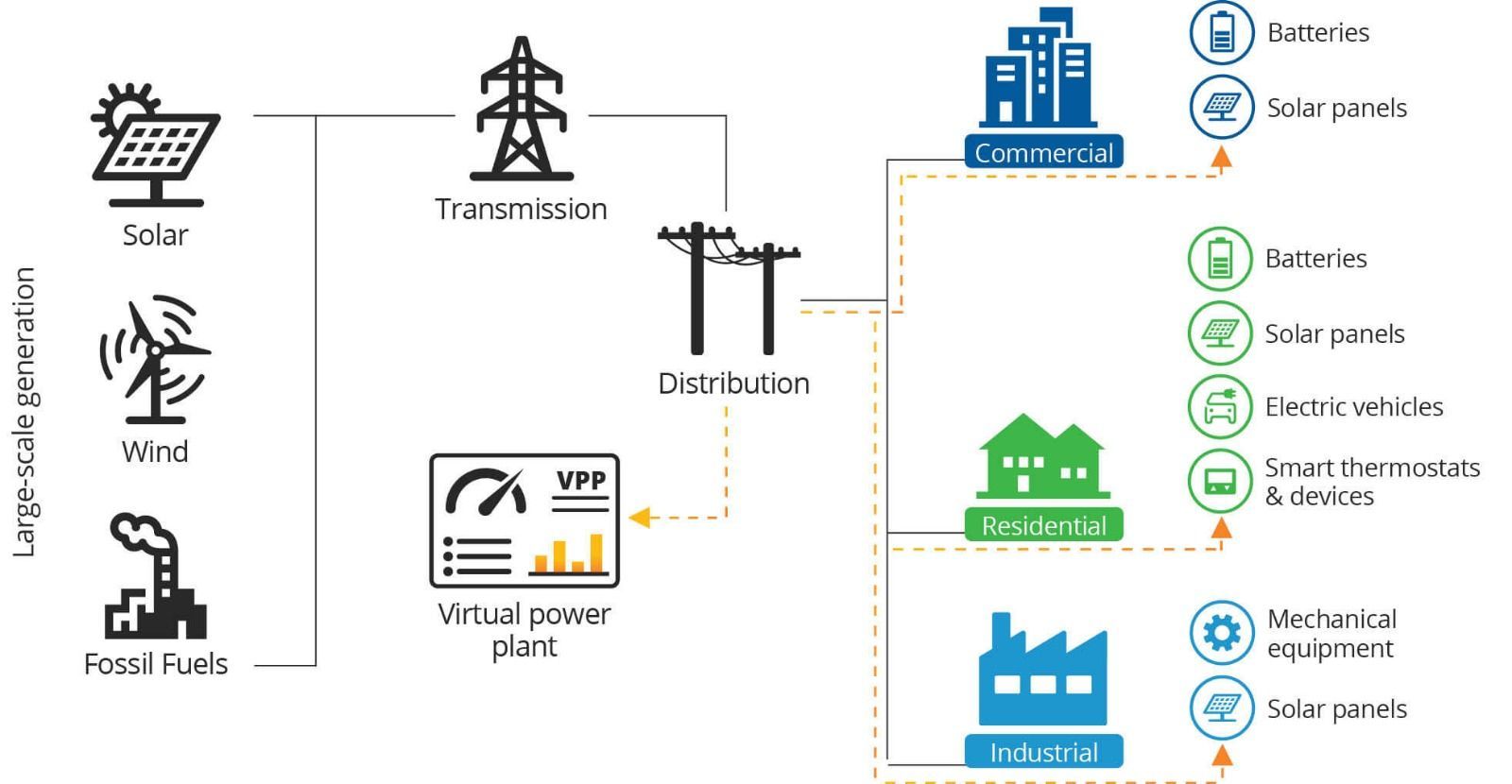

| VPP capacity (Lunar Energy) | 650 MW |

| Lunar funding raised | US$232 million |

| Data center BESS example | 31 MW / 62 MWh |

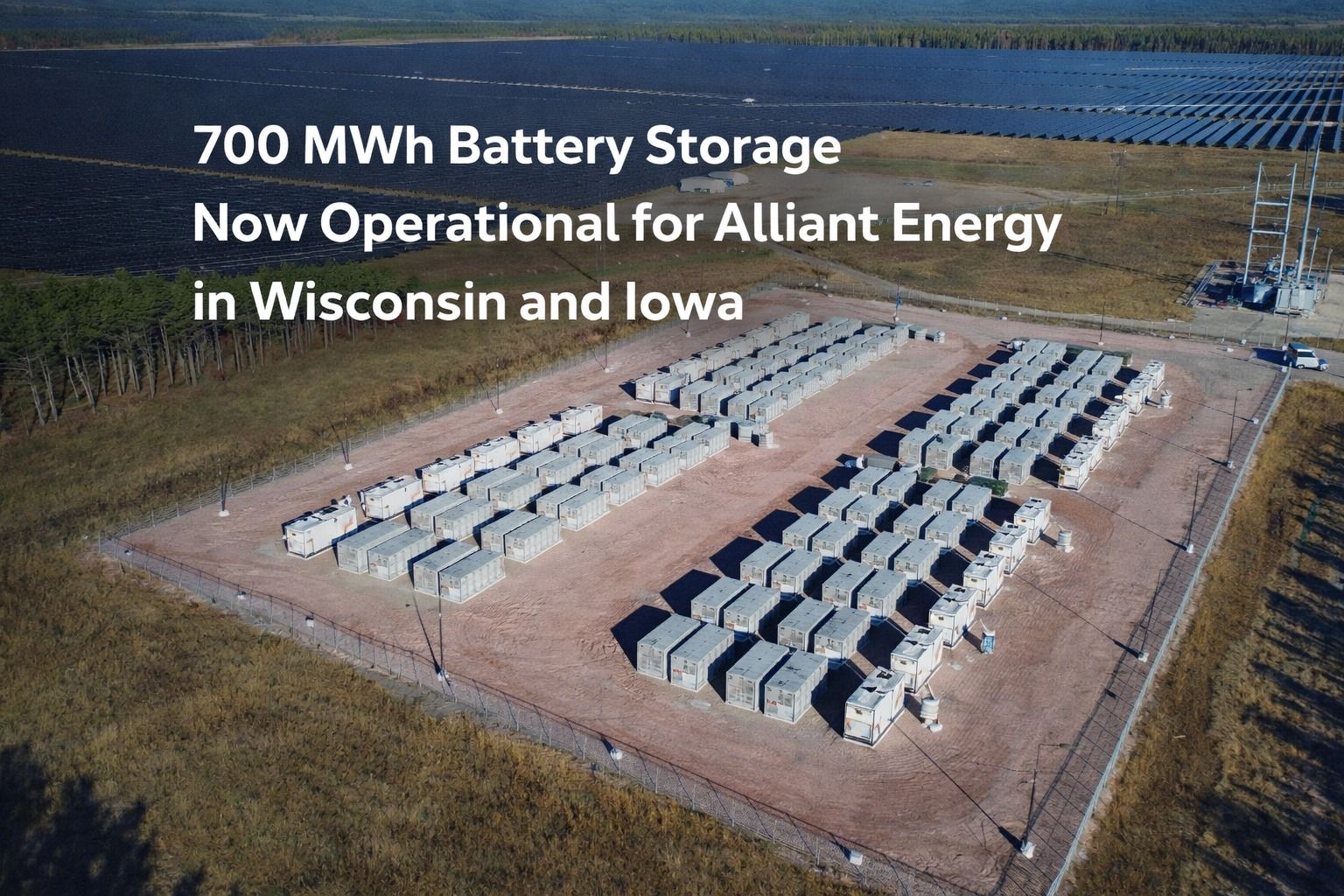

| ERCOT grid-scale batteries | 15+ GW |

| LDES tenders (H1 2026) | Up to 9.3 GW |

| Lithium-ion share of LDES by 2030 | 77% |

| FEOC initial threshold | 55% |

| BESS tariff rate (2026) | ~55% |

| Capacity gain from analytics | 5–15% |

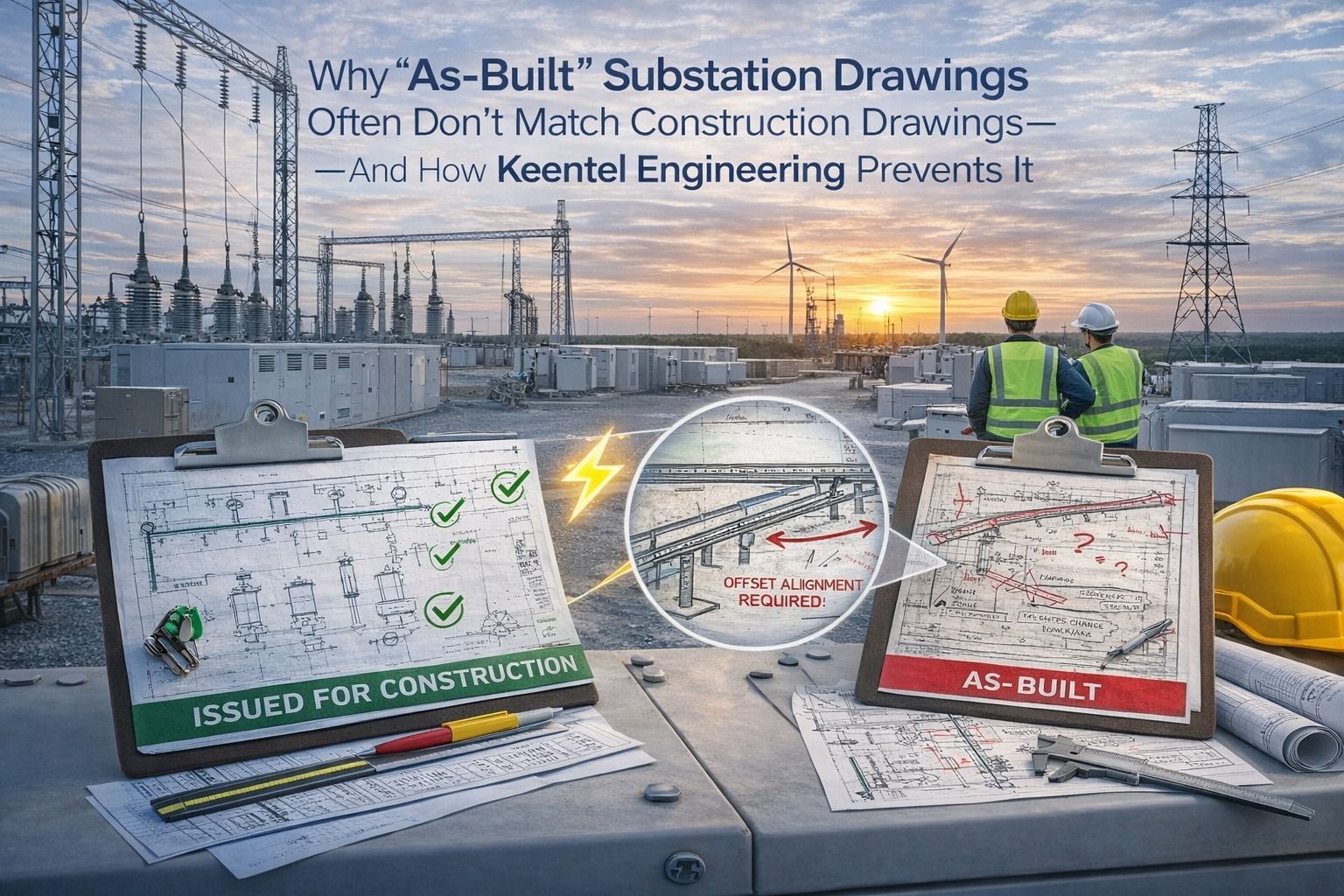

Why “As-Built” Substation Drawings Often Don’t Match Construction Drawings And How Keentel Engineering Prevents It

February 19, 2026 | Blog

Introduction: The Hidden Cost of Drawing Mismatches

In substation projects, one of the most costly and frustrating issues occurs when as-built drawings barely resemble the issued-for-construction (IFC) drawings.

When this happens, it typically leads to:

- Budget overruns

- Project delays

- Construction rework

- Procurement conflicts

- Engineering redesign

- Operational confusion

At Keentel Engineering, we specialize in eliminating these risks by integrating constructability, QA/QC, procurement alignment, and field expertise into every substation design project.

Why Do As-Built Drawings Differ from Construction Drawings?

Through decades of industry experience, three primary causes consistently emerge:

- Failure to verify existing site conditions

- Designing without understanding construction practices

- Weak or rushed QA/QC processes

Let’s examine each and how Keentel Engineering addresses them.

1. When Drawings Don’t Match the Real World

One of the most common causes of field changes is the discrepancy between design drawings and actual site conditions especially in brownfield substations.

Typical Issues Include:

- Outdated record drawings

- Underground congestion not documented

- Equipment removals or additions not reflected

- Previous field markups never incorporated

Keentel Engineering’s Approach:

We prevent these issues by requiring:

- Mandatory site walkdowns before major design phases

- Physical verification of equipment and clearances

- Soil resistivity testing for grounding design

- Foundation condition assessments

- Grounding system testing

- Cross-checking legacy drawings against real conditions

We design based on reality not assumptions.

2. Theory vs. Practice: Designing Without Constructability

Engineering theory alone does not guarantee constructability.

For example:

- A 3-conductor 500 kcmil cable may look efficient on paper, but can be extremely difficult to pull, splice, and terminate.

- Replacing transformers may appear simple until operational constraints, temporary phasing, and space limitations are considered.

Designers without field experience often overlook:

- Cable pulling tensions

- Conduit bend radii

- Equipment access for cranes

- Maintenance clearance

- Temporary transformer placement

- Real estate constraints in energized yards

Keentel’s Constructability Integration

At Keentel Engineering, we:

- Involve construction professionals early

- Model phasing sequences

- Validate access routes and lifting plans

- Check conduit fill and cable pulling feasibility

- Evaluate staging areas

- Ensure maintainability is designed in

Constructability is engineered into the design not discovered in the field.

3. Poor Drawing Quality

Field markups often stem from poor drawing quality, including:

- Inconsistent labeling (e.g., GCB vs BKR references)

- Copy-paste errors

- Inconsistent foundation details

- Missing material callouts

- Overcrowded or unclear drawings

- Incorrect material specifications

Drawings are construction instructions. If instructions are unclear, construction slows down.

Keentel Engineering’s QA/QC Framework

A strong Quality Assurance / Quality Control program reduces total project cost by preventing field errors before construction begins.

Quality Control (QC)

- 100% detailed drawing review

- Cross-discipline checks

- Material schedule verification

- Conduit and cable tray capacity checks

- Protection and control consistency review

Quality Assurance (QA)

- Senior engineer oversight

- Constructability validation

- Owner standard compliance

- Review milestone enforcement

Our QA/QC system ensures drawings are:

- Precise

- Consistent

- Complete

- Buildable

This dramatically reduces RFIs and field markups.

The Critical Role of Scheduling

Aggressive project schedules often compromise quality.

When engineering timelines are compressed:

- Vendor drawings arrive late

- QA/QC gets rushed

- Procurement decisions are delayed

- Critical path coordination fails

Keentel’s Scheduling Methodology

We integrate:

- Engineering fact-finding phase

- Early engineering decision deadlines

- Milestone reviews (30% / 90%)

- Procurement alignment

- Critical path coordination

- Vendor drawing tracking

Large transformers, steel structures, and control panels often have long lead times. Engineering must align with procurement not react to it.

The 30% and 90% Review Milestones

30% Review – Early Design Validation

Includes:

- Single-line diagram

- Yard general arrangement

- Foundation concepts

- Elevation views

At this stage:

- Layout is validated

- Constructability is reviewed

- Major procurement decisions are authorized

Changes after this point are expensive and disruptive.

90% Review – Final Pre-Construction Validation

This is the final opportunity to verify:

- Conduit routing

- Bus detailing

- Wiring diagrams

- Foundation details

- Protection schematics

Construction teams review drawings as if they are building from them.

Keentel ensures this milestone is never rushed.

Procurement Integration: Avoiding Field Delays

Modern manufacturing requires long lead times.

If procurement is not synchronized with engineering:

- Materials arrive late

- Foundation designs stall

- Construction pauses

- Costs escalate

Keentel Engineering:

- Tracks vendor drawing submissions

- Verifies material conformity

- Ensures all materials shown are clearly specified

- Aligns procurement milestones with engineering releases

No assumptions. No missing parts. No surprises.

Post-Project Review: Continuous Improvement

After project completion, Keentel conducts:

- Field markup analysis

- Root cause evaluations

- Lessons-learned workshops

- Process updates

This feedback loop strengthens future projects.

The Importance of Team Selection

Successful substation projects require team members with:

- Construction experience

- Mechanical aptitude

- Organizational skills

- Strong communication ability

Communication is not just talking it’s listening across engineering, procurement, construction and operations.

Keentel Engineering builds multidisciplinary teams that collaborate from project start to commissioning.

The Three Pillars of Substation Project Success

Every successful substation project rests on:

1. Experience

Understanding both engineering theory and field reality.

2. Quality

Delivering consistent, accurate, and complete drawings.

3. Communication

Aligning engineering, procurement, and construction continuously.

Keentel Engineering integrates all three into every project.

20 Frequently Asked Questions (FAQs)

1. Why do as-built drawings often differ from construction drawings?

Because field changes occur due to inaccurate site data, constructability oversights, or rushed QA/QC.

2. How can field changes be minimized?

Through site verification, early constructability reviews, and disciplined QA/QC processes.

3. What is the difference between QA and QC?

QC is a detailed technical review. QA is senior-level oversight ensuring process compliance and constructability.

4. Why is the 30% review important?

It validates layout and major decisions before procurement begins.

5. What happens if procurement starts too early?

Late design changes become costly and delay construction.

6. How does inconsistent labeling affect construction?

It creates confusion, RFIs, and delays in the field.

7. Why must construction teams review drawings?

They validate real-world buildability and installation feasibility.

8. Why are soil tests critical in substation projects?

They determine foundation design and grounding system performance.

9. How do aggressive schedules affect design?

They reduce QA/QC time and increase error risk.

10. What is the project critical path?

The sequence of tasks that determines the project completion date.

11. Why is procurement alignment important?

Engineering depends on vendor data to finalize foundations and structural details.

12. What is constructability?

Designing with actual construction methods, sequencing, and access in mind.

13. How does Keentel reduce total project cost?

By preventing rework and minimizing field markups through rigorous design control.

14. What role does communication play?

It prevents small coordination issues from becoming major construction problems.

15. Why is post-project review important?

It improves future projects through lessons learned.

16. What is the biggest mistake in substation design?

Ignoring site conditions and real construction practices.

17. How are conduit congestion issues prevented?

Through early capacity analysis and field-experience review.

18. Why are vendor drawings critical?

They impact foundation design and equipment installation accuracy.

19. What skills are most important in a substation project team?

Construction awareness, communication, organization, and technical expertise.

20. Why choose Keentel Engineering?

Because we design substations that are accurate, constructible, coordinated, and built correctly the first time.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.