A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

High-Fidelity PSCAD Modeling of Electric Arc Furnaces: Engineering Challenges and Solutions

October 01, 2025 | Blog

Introduction

Electric Arc Furnaces (EAFs) and Ladle Furnaces (LFs) are essential components of modern steelmaking. Their dynamic and highly nonlinear electrical behavior, however, presents unique challenges for power system planners and utilities. Rapid current fluctuations, high harmonic distortion, and voltage flicker make arc furnaces one of the most demanding industrial loads to model accurately.

Conventional steady-state tools such as PSSE, PSLF, or DigSILENT PowerFactory are suitable for power flow and short-circuit studies, but they lack the resolution needed to capture the sub-cycle dynamics of the arc. For this reason, Electromagnetic Transients (EMT) simulation using PSCAD or EMTDC has become the standard for evaluating arc furnace impacts on the grid.

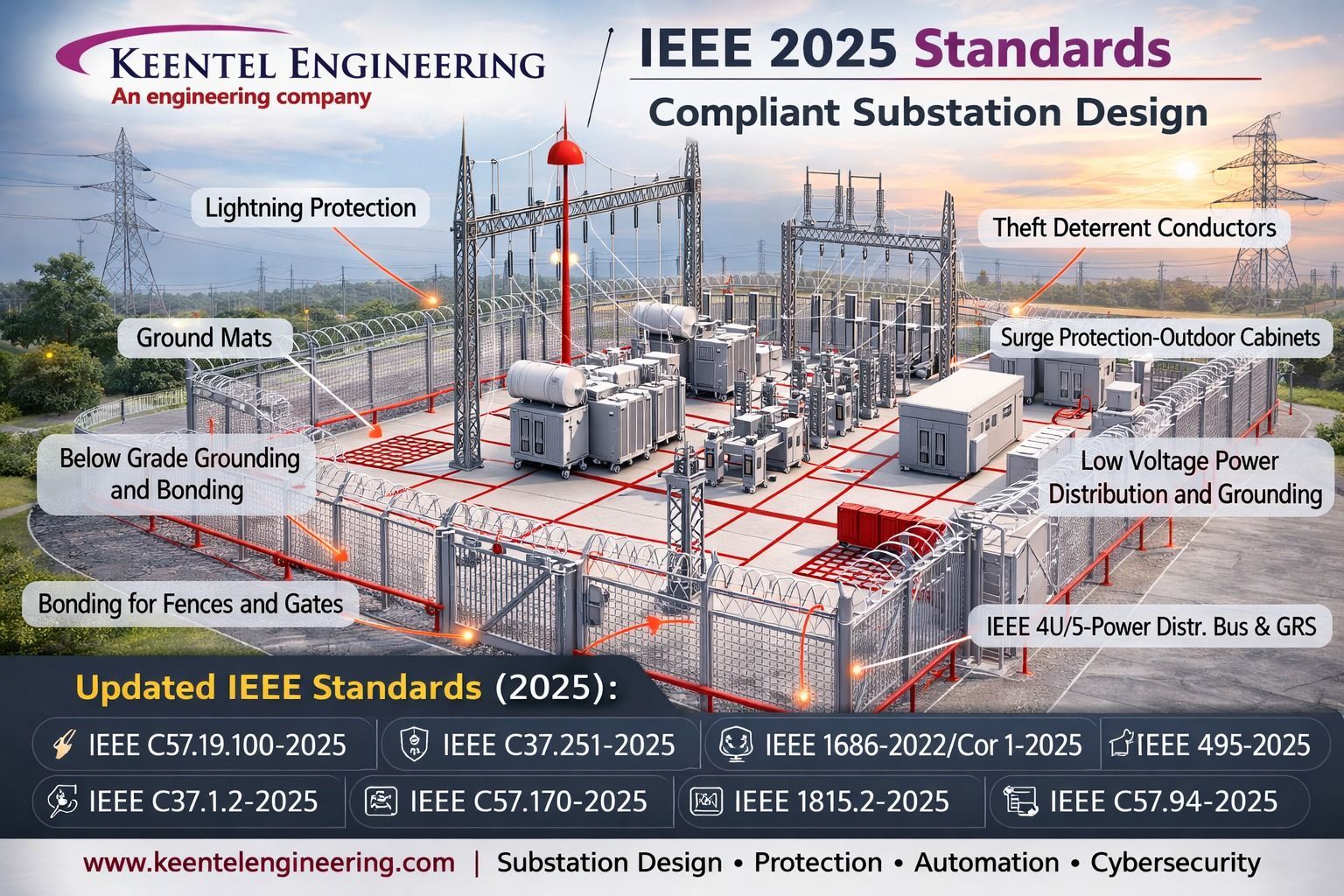

At Keentel Engineering, we specialize in developing custom PSCAD models of EAF and LF systems, enabling both utilities and industrial operators to understand system interactions, mitigate risks, and ensure compliance with interconnection requirements. This blog provides a detailed overview of how such models are developed, what data is required, typical deliverables, and the challenges that engineers must overcome.

Read more about our

EMT Analysis for Power Systems and why sub-cycle dynamics matter in grid planning.

Why PSCAD Models are Needed for Arc Furnace Studies

EAFs differ from most industrial loads because of their nonlinear and time-varying nature. During operation, the furnace arc behaves like a rapidly changing resistance, generating:

- Voltage flicker: Light intensity fluctuations due to arc instability.

- Harmonics: A wide spectrum of harmonic currents, especially 2nd, 3rd, 5th, 7th, and 11th orders.

- Unbalance: Unequal phase currents due to irregular arc behavior.

- Transients: Sudden current surges during electrode ignition or shorting events.

Traditional phasor-domain tools average these effects, masking the true waveform distortions seen at the point of interconnection (POI). EMT tools like PSCAD allow engineers to:

- Model arc dynamics in the time domain (microsecond resolution).

- Simulate random/stochastic variations in arc length and resistance.

- Evaluate flicker indices (Pst, Plt) according to IEC 61000-4-15.

- Assess harmonic distortion against IEEE 519 limits.

- Validate short-term ride-through and stability under voltage sags.

See our guide on

Power System Stability with PSS®E, TSAT, and PSCAD to compare tools and approaches.

Problem Statement: Challenges in Modeling Arc Furnaces

Developing an accurate PSCAD model of an EAF is not trivial. The main challenges include:

- Arc Nonlinearity: The V–I characteristic of an arc is not a simple curve. It changes with arc length, electrode material, and operating stage (ignition, bore-in, flat bath).

- Stochastic Behavior: Arc voltage fluctuations are random in nature. Reproducing realistic stochastic patterns requires statistical modeling and calibration against measured data.

- Furnace Duty Cycles: Modern Consteel® furnaces operate in continuous melting mode but require cold-start bucket charging every two weeks. Both cycles must be represented in the model.

- Control System Dynamics: Electrode regulators react within tens of milliseconds to stabilize the arc. Their performance strongly affects flicker and harmonic emissions.

- System Interactions: EAFs are often connected through large transformers and reactors that add complexity to voltage regulation and fault response.

- Validation Requirements: Utilities require models to be validated against measured waveforms, ensuring that flicker indices and harmonic spectra match real-world conditions.

Explore our Relay Modeling & Protection Simulation services to see how controls and protection systems are validated.

PSCAD Modeling for Arc Furnaces

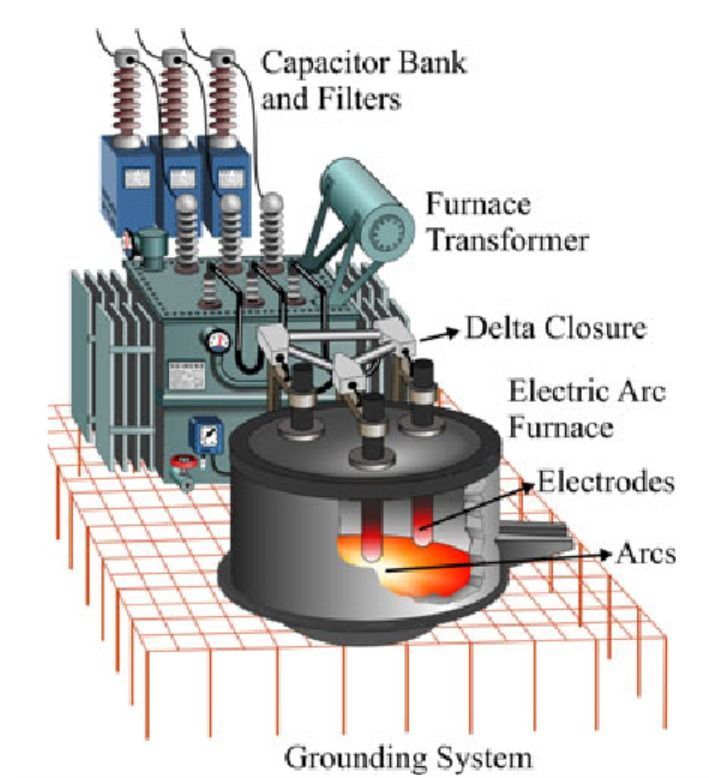

A complete PSCAD model of an EAF/LF system typically includes the following components:

1. Furnace Transformers

- MVA rating, voltage ratio, and tap-changer details.

- Leakage reactance and X/R ratio.

- Nonlinear saturation curve for energization studies.

2. Series Reactors

- Frequency-dependent inductance and resistance.

- Damping of current harmonics.

3. Arc Furnace Model

- Nonlinear V–I characteristic of the arc.

- Stochastic/random variation of arc length.

- Electrode regulator dynamics.

- Asymmetry and unbalance modeling.

- Melting cycle representation (ignition, bore-in, flat bath, cold-start).

4. Harmonic & Flicker Representation

- Harmonic current injections up to the 20th harmonic.

- Flicker module calculating Pst and Plt indices.

5. Auxiliary Loads

- Motor loads (rolling mill drives, pumps, fans).

- Static ZIP loads for balance.

6. Protection and Control

- Relay settings (overcurrent, undervoltage, differential).

- Breaker clearing times.

- Furnace trip logic under severe disturbances.

Typical Deliverables from a PSCAD Model Development Project

When an engineering firm like Keentel develops an EAF PSCAD model, the following deliverables are usually provided:

- Model Specification Document: Defines assumptions, modeling methodology, and data requirements.

- Transformer & Reactor Models: PSCAD blocks for transformers and series reactors.

- Arc Furnace Model: Complete furnace with electrode dynamics and stochastic arc behavior.

- Harmonic & Flicker Modules: Representation of emissions and flicker indices.

- Validation Report: Comparison of simulated results with measured waveforms.

- PSCAD Project Files: Fully functional models with modular structure.

- Parameter File: Separate dataset file allowing easy tuning of parameters.

- User Manual: Instructions for running and modifying the model.

- Training Session: Remote demonstration for engineers on model operation.

Data Requirements for Accurate Modeling

The quality of a PSCAD model depends directly on the data provided.

Must-Have Data

- Transformer nameplate ratings and impedance.

- Arc furnace rated MW/Mvar demand.

- V–I curve of the arc.

- Electrode regulator philosophy.

- At least one measured dataset of currents and voltages.

Assumable Data (if missing)

- Transformer saturation curve.

- Stochastic arc parameters.

- Harmonic emission spectrum (based on literature/IEEE).

- Auxiliary motor dynamics (based on NEMA standards).

- Relay settings (based on IEEE C37 defaults).

Keentel Engineering documents all assumptions in the Model Specification Document to maintain transparency and traceability.

Validation of PSCAD Models

Validation is the most critical step. Without it, the model remains theoretical.

- Measured Datasets: Typically, waveforms are recorded at high sampling rates (e.g., 1600 Hz).

- Calibration Process: Model parameters are adjusted until simulated waveforms align with measured data.

- Metrics Used:

- Current and voltage waveforms.

- Flicker indices (Pst, Plt).

- Harmonic distortion (THD, individual harmonics).

A well-calibrated model gives utilities confidence that study results reflect real-world conditions.

Learn how our

MOD-033-1 Model Validation Services ensure that simulations align with measured waveforms.

Applications of EAF PSCAD Models

- System Impact Studies: Evaluate voltage flicker, harmonics, and unbalance at the POI.

- Filter Design: Optimize SVCs and harmonic filters for compliance.

- Ride-Through Studies: Assess furnace behavior under grid disturbances.

- Operational Planning: Simulate continuous and cold-start cycles for scheduling impacts.

- Training: Provide engineers with a virtual environment to study EAF-grid interactions.

Applications of EAF PSCAD Models

- Limited Data Availability

- Solution: Use IEEE/IEC benchmark values and document assumptions clearly.

- Arc Randomness

- Solution: Incorporate stochastic functions in PSCAD (Gaussian or uniform random variables).

- Complex Electrode Controls

- Solution: Simplify regulator model while preserving essential dynamics (10–50 ms response).

- Computational Demands

- Solution: Modularize the model and optimize time step (e.g., 50 μs) to balance accuracy and speed.

Conclusions

High-fidelity PSCAD modeling of arc furnaces is indispensable for modern steel plants and utilities. It enables engineers to predict flicker, harmonics, and transient interactions with confidence, ensuring compliance with grid codes and reliable operation.

Keentel Engineering combines domain expertise in power system studies with custom PSCAD modeling capabilities to deliver robust solutions for challenging industrial loads.

Frequently Asked Questions

1. Why can’t arc furnaces be modeled accurately in PSSE or PSLF?

Because phasor-domain tools average system variables over a cycle, they cannot capture the sub-cycle fluctuations of the arc. PSCAD operates in the time domain with microsecond resolution, making it suitable for nonlinear, random arc dynamics.

2. What is the typical time step used in PSCAD arc furnace models?

A typical time step ranges from 20 to 50 microseconds, depending on harmonic resolution requirements and simulation stability.

3. How are stochastic arc variations represented?

Stochastic behavior is modeled using random number functions that vary arc resistance or voltage within defined limits, based on measured statistical distributions.

4. What standards govern flicker limits for EAFs?

The main standard is IEC 61000-3-7 (flicker planning levels), while utilities often set limits of Pst ≤ 0.8 and Plt ≤ 0.6 at the POI.

5. What are the most dominant harmonics from an EAF?

Typically the 2nd, 3rd, 5th, 7th, 11th, and 13th harmonics dominate, though actual spectra vary with arc stability and operating stage.

6. Can the model include auxiliary loads like motors?

Yes. Large motors (e.g., rolling mills, pumps) can be added as dynamic motor models, while smaller loads are represented as static ZIP models.

7. How is model validation performed?

Validation requires measured waveforms of voltage and current. The model is tuned until simulated flicker indices, harmonic spectra, and transient responses match measured values.

8. What if measured data is not available?

Benchmark models from IEEE or CIGRÉ can be used, but results must be treated as indicative rather than definitive. For interconnection studies, utilities usually require at least one measured dataset.

9. How long does PSCAD model development take?

A typical project requires 10–14 weeks, including data review, model development, validation, and documentation.

10. Can PSCAD models be shared with utilities directly?

Yes. Models are usually delivered in PSCAD project format with parameter files, allowing utilities to run their own test cases.

11. What type of data is most critical for model success?

The arc V–I curve, transformer parameters, and measured datasets are the most critical. Without them, the model cannot be validated.

12. How are cold-start cycles represented?

Cold-start is modeled as a transient high-disturbance phase with rapidly varying arc resistance and high flicker emission, calibrated against measured cold-start data.

13. Why include electrode regulator dynamics?

Because regulator speed determines how quickly the arc stabilizes after disturbances. Faster regulators reduce flicker but may inject more harmonics.

14. How are harmonics modeled?

Either by direct time-domain simulation of arc current distortions or by injecting harmonic current sources tuned to measured spectra.

15. Can SVCs or filters be integrated into the model?

Yes. PSCAD allows detailed modeling of SVCs (TCR, TSC) and passive filters, enabling joint furnace–compensation studies.

16. What are typical validation accuracy criteria?

±5% deviation in RMS currents/voltages, ±10% deviation in flicker indices, and ±1% in harmonic distortion compared to measurements.

17. How are auxiliary motors represented in PSCAD?

As dynamic motor models with inertia, torque-speed curves, and electrical characteristics. Smaller motors can be lumped into static loads.

18. Do utilities require EMT models for all industrial loads?

Not always. EMT models are specifically requested for arc furnaces, HVDC links, and inverter-based resources, where nonlinear dynamics matter.

19. What happens if model assumptions differ from reality?

Assumptions are clearly documented, and sensitivity studies are performed to evaluate how uncertainties affect results.

20. Can PSCAD models be reused for future projects?

Yes. Models are modular and can be adapted to different furnace sizes or configurations by adjusting parameter

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.

Related Posts