A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Challenge: Frequent false tripping using conventional electromechanical relays

Solution: SEL-487E integration with multi-terminal differential protection and dynamic inrush restraint

Result: 90% reduction in false trips, saving over $250,000 in downtime

Comprehensive Power System Analysis for Industrial Reliability and Safety

October 10, 2025 | Blog

Introduction

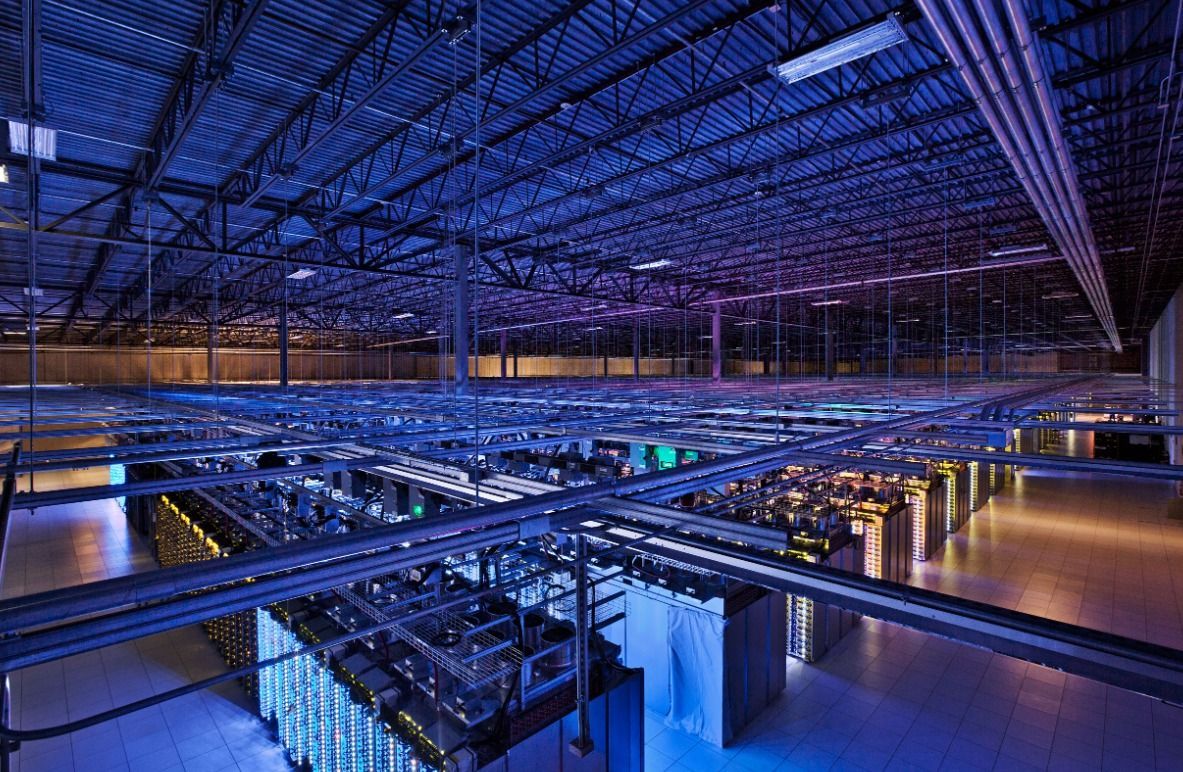

In every modern industrial facility, electrical reliability is not optional — it’s essential. From manufacturing plants to data centers, the seamless operation of equipment depends on precise voltage regulation, effective protection, and system stability.

That’s where power system analysis becomes indispensable.

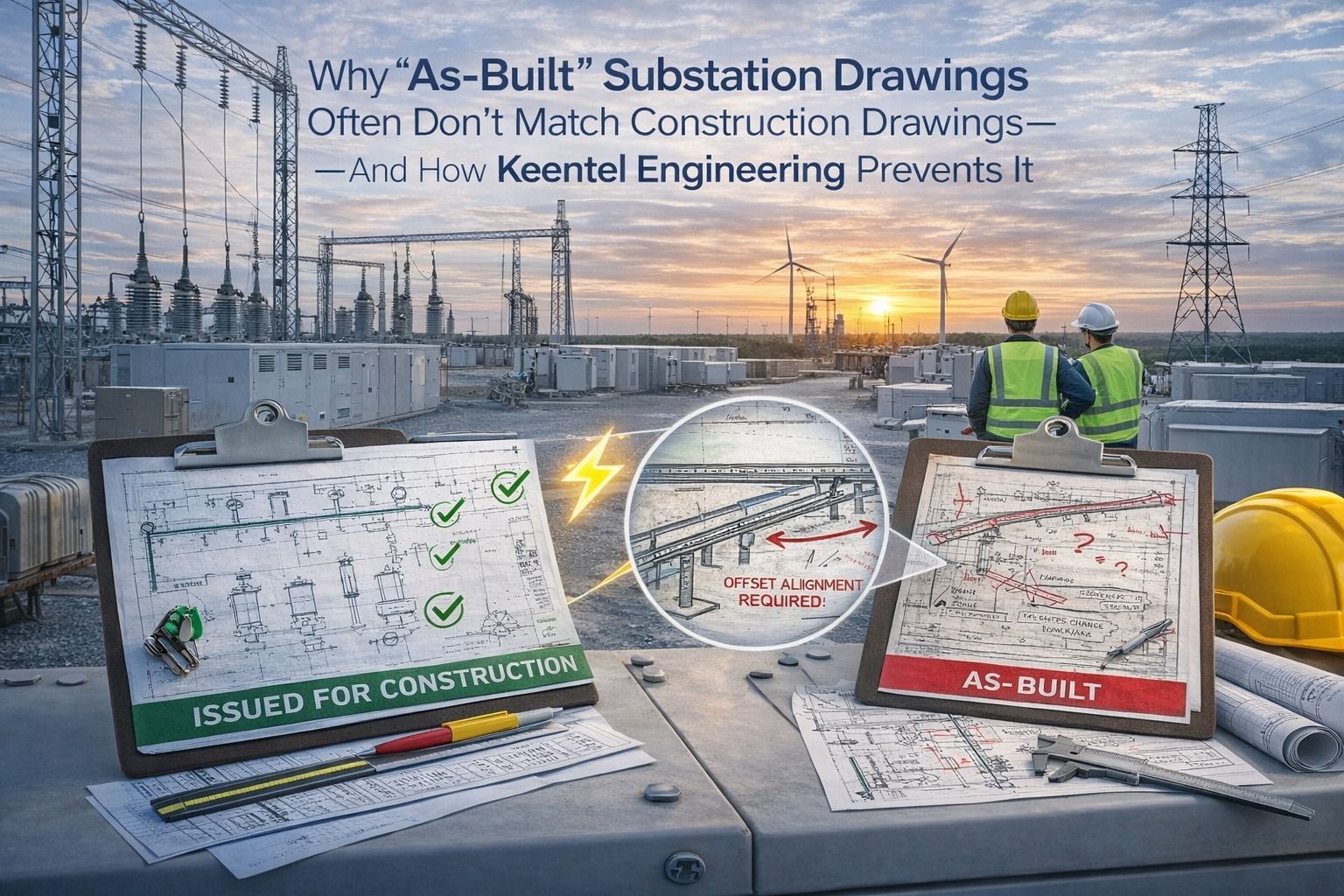

Keentel Engineering delivers comprehensive analytical solutions that enable industrial operators to design, verify, and maintain power systems that are safe, resilient, and cost-effective. These studies help engineers predict how systems behave under normal and fault conditions, ensuring optimized performance, protection, and compliance.

1. Why Power System Analysis Matters

Power system analysis allows engineers to evaluate performance parameters such as voltage, current, short-circuit strength, and transient behavior before any physical fault or outage occurs.

It ensures:

- Safety — Proper protection coordination prevents catastrophic faults.

- Reliability — Systems continue operating even during disturbances.

- Efficiency — Energy losses and downtime are minimized.

- Compliance — Designs meet IEEE, NEC, and NERC standards.

In short, it transforms reactive troubleshooting into proactive engineering.

2. Essential Power System Studies

a. Short-Circuit Analysis

A short-circuit study determines the maximum fault current available at various points in the network. It forms the basis for:

- Selecting proper switchgear and protective devices

- Assessing the mechanical and thermal stress on cables and transformers

- Defining current-limiting reactor needs

By simulating both three-phase and ground faults, Keentel engineers verify breaker interrupting ratings and ensure system integrity.

b. Protective Device Coordination

Protective device coordination ensures that only the faulty section of a network is isolated while the rest remains energized.

Using time-current characteristic (TCC) curves, engineers optimize relay and fuse settings to balance selectivity and speed.

This coordination approach minimizes downtime, prevents unnecessary tripping, and supports uninterrupted industrial processes.

c. Load-Flow (Power Flow) Studies

Load-flow analysis evaluates voltage profiles, power losses, and reactive compensation across the system. It helps determine:

- Optimal transformer tap settings

- Power factor correction needs

- Proper cable sizing and loading

This steady-state simulation provides a clear roadmap for system expansion, ensuring voltage stability and balanced operation under all load conditions.

d. Transient Stability Studies

Transient stability analysis examines how a system reacts to disturbances like short circuits or generator outages.

It verifies that synchronous generators remain in step and stable after faults.

These studies are vital for plants with local generation. They determine critical clearing times, load-shedding settings, and generator protection parameters, preventing costly blackouts and equipment damage.

e. Motor Starting Studies

Large motor startups can cause voltage dips and torque instability.

By simulating motor starting sequences, Keentel Engineering ensures sufficient voltage is available across the system without jeopardizing sensitive equipment.

The analysis defines acceleration torque, inrush current, and voltage drop limits to guarantee smooth startup performance.

f. Grounding and Transient Overvoltage Studies

Effective grounding and surge analysis protect industrial assets from insulation breakdown, resonance, and dangerous touch potentials.

These studies include:

- Evaluating zero-sequence impedance and grounding resistance

- Assessing switching surge transients

- Recommending surge protection and grounding system improvements

A properly grounded network dramatically enhances both safety and system longevity.

3. Engineering Data for Accurate Results

Accurate studies depend on detailed input data. Keentel’s engineering process collects:

- Transformer impedance, tap ratios, and MVA ratings

- Generator constants, excitation data, and inertia coefficients

- Motor characteristics including reactances, resistances, and starting profiles

- Cable and bus configurations with conductor lengths and spacing

- Relay types, CT/PT ratios, and protection logic

This ensures every simulation represents the actual electrical environment with high fidelity.

See our

Power System Study Solutions for complete short-circuit, coordination, and stability modeling.

4. When Should Power System Studies Be Conducted?

Keentel Engineering recommends conducting comprehensive studies at various stages of a system’s lifecycle. During new system design, it is essential to perform short-circuit, load-flow, transient-stability, and grounding analyses to ensure the system’s reliability and safety from the outset. When system modifications occur — such as the addition of new loads or generation sources — updated short-circuit and coordination studies are necessary to maintain proper system performance and protection. In troubleshooting scenarios, focused studies should be carried out to address issues like instability, overvoltage, or protection failures. Additionally, periodic re-evaluation every three to five years is advised to ensure the system remains compliant with current standards and optimized for evolving operational demands.

5. The Keentel Engineering Advantage

Keentel Engineering applies advanced software platforms — including PSSE, ETAP, PSCAD, and PowerFactory — to model complex industrial grids with precision.

Our expertise spans:

- High-Voltage (HV) and Medium-Voltage (MV) systems

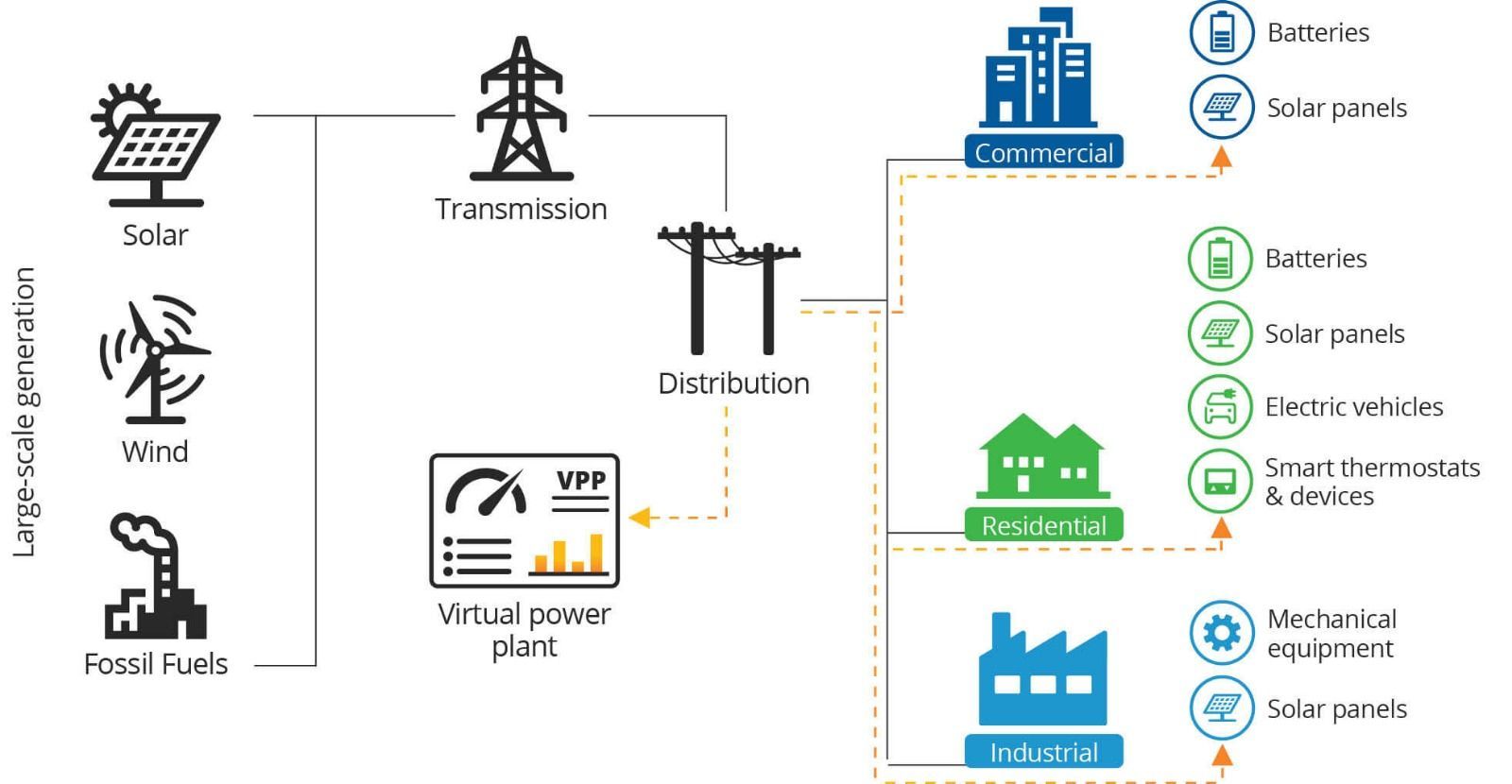

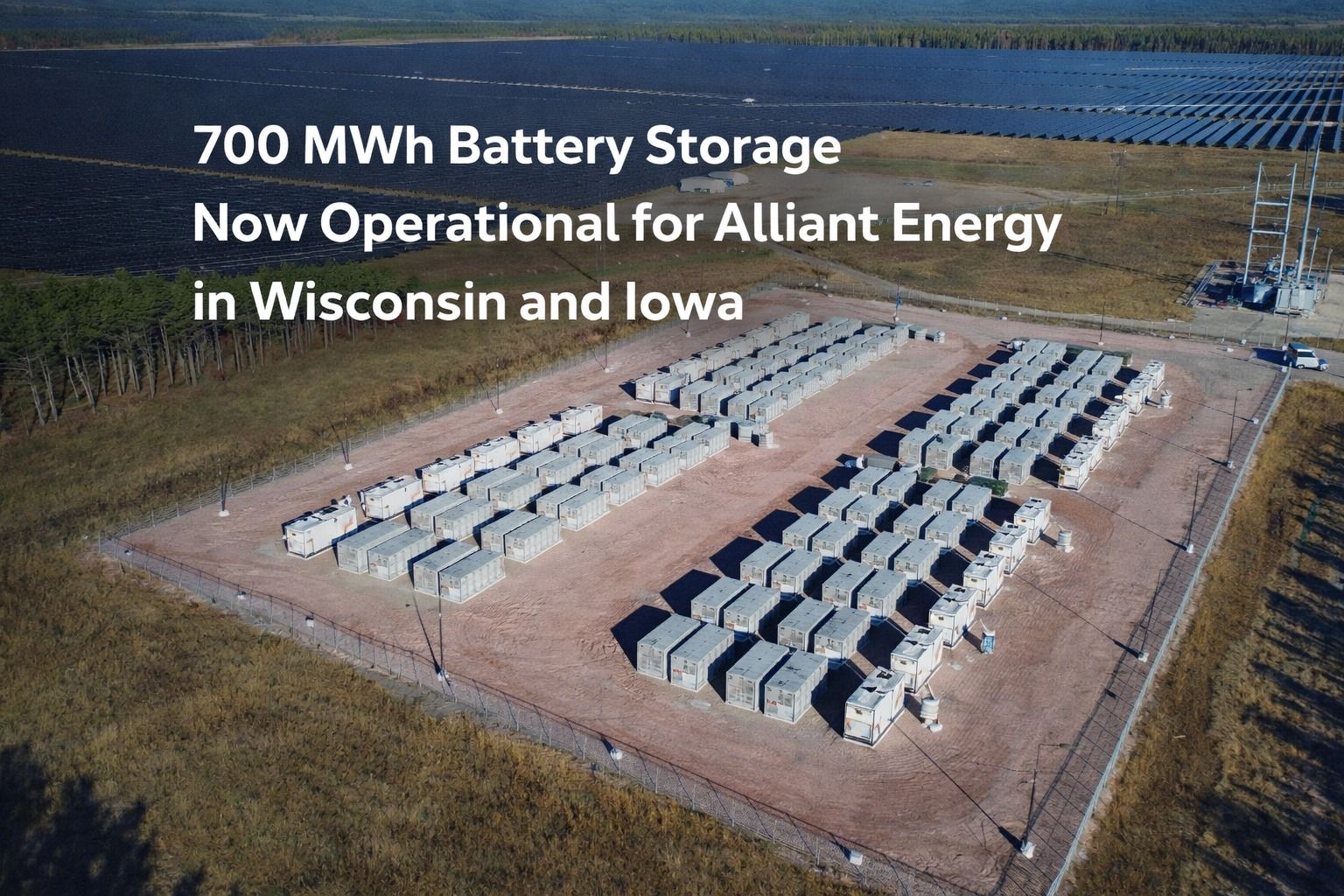

- Renewable integration and generator interconnection

- Relay coordination and system grounding optimization

Our engineers deliver data-driven, IEEE-compliant recommendations tailored to your operational and safety requirements.

Explore our

Power System Modeling Services to ensure accurate simulations using ETAP, PSSE, and PSCAD.

Conclusions

Power system analysis is far more than a compliance exercise — it’s the backbone of safe and efficient electrical design.

By combining simulation, experience, and system understanding, Keentel Engineering ensures that industrial power systems achieve maximum reliability, stability, and cost-efficiency.

For consultation, detailed modeling, or complete study packages, contact Keentel Engineering today to fortify your electrical infrastructure against tomorrow’s challenges.

Frequently Asked Questions – Power System Analysis

1. What is a power system study?

It’s a detailed simulation of an electrical network used to analyze performance under both normal and fault conditions.

2. Why are short-circuit studies necessary?

They ensure equipment can safely interrupt fault currents and prevent catastrophic failures.

3. How are protective device settings optimized?

Using TCC curves and coordination analysis to ensure selective isolation without system-wide shutdowns.

4. What does a load-flow study determine?

It reveals bus voltages, power losses, and line loading, ensuring proper system balance.

5. What’s the significance of transient stability analysis?

It evaluates how generators react during faults, preventing loss of synchronism.

6. How can system reliability be increased through coordination?

By ensuring only the affected circuit disconnects, leaving the rest of the network energized.

7. Why is grounding design critical?

It mitigates transient overvoltages, improves safety, and stabilizes fault currents.

8. How often should studies be updated?

Every time new equipment, loads, or distributed generation are added — typically every 3–5 years.

9. What are symmetrical components?

They decompose unbalanced currents and voltages into balanced sets, simplifying fault analysis.

10. How are motor starting issues prevented?

By simulating start-up scenarios to avoid voltage dips and mechanical torque problems.

11. What software tools does Keentel use?

Industry-standard platforms like ETAP, PSSE, PowerFactory, PSCAD, and MATLAB/Simulink.

12. What causes transient overvoltage in plants?

Switching operations, lightning, arcing faults, and harmonic resonance.

13. How does load flow relate to stability studies?

The steady-state data from load-flow analysis forms the initial condition for stability simulations.

14. What data are most crucial for accurate results?

Transformer impedance, generator constants, and relay characteristics.

15. How are underfrequency relays set?

Using transient stability simulations that calculate frequency decay after generator loss.

16. Can system analysis improve energy efficiency?

Yes — load-flow optimization reduces reactive losses and enhances power factor.

17. Why do large motors affect system voltage?

Their high inrush currents cause voltage drops that can disrupt nearby loads.

18. What is coordination time interval (CTI)?

The time margin between two protective devices ensuring proper selectivity.

19. How are surge and grounding studies performed?

By simulating transient behavior and verifying compliance with IEEE and NEC grounding criteria.

20. Why partner with Keentel Engineering?

Keentel combines decades of field experience with advanced analytical software to deliver robust, reliable, and standards-compliant power system solutions.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.