A Coordinated Electric System Interconnection Review—the utility’s deep-dive on technical and cost impacts of your project.

Essential Steps for Commissioning Circuit Breakers

April 1, 2023 | Blog

Introduction of Commissioning Circuit Breakers

Commissioning circuit breakers is a critical process to ensure the reliability, safety, and functionality of switchgear systems in substations and power facilities. Proper commissioning ensures that each circuit breaker operates according to design specifications and regulatory standards—including those outlined in NERC PRC requirements.

This guide outlines the essential steps for circuit breaker commissioning, covering electrical, mechanical, and functional performance.

Need expert commissioning support? Explore our Substation Design Services for turnkey engineering and testing solutions.

Essential Steps for Commissioning Circuit Breakers

1. Verification of Control Wiring

Meticulously inspect control wiring for correct connections, continuity, and insulation resistance (IR) values. This ensures reliable control circuit operation.

2. Manual Operation

Next, manually operate the breaker to test its functionality. This involves physically operating the breaker to ensure smooth movement and alignment with its intended positions.

3. Power Closing and Operating Tests

Test the breaker's ability to close and open under both manual and electrical operations. This confirms its readiness to handle operational loads and fault currents.

4. Tripping and Closing Time

Measure and record the breaker’s response time. Fast and accurate trip/close timing is essential for minimizing fault duration and improving grid stability.

5. Trip-Free and Anti-Pumping Operation

Verify the trip-free mechanism to ensure the breaker will open during faults even under manual closure attempts. Check anti-pumping to prevent multiple closings during sustained fault conditions.

6. IR Values, Resistance, and Minimum Pickup Voltage

Measure insulation resistance (IR), internal resistance, and minimum pickup voltage. Low IR or abnormal resistance can lead to future insulation breakdowns or overheating.

7. Contact Resistance

Measure contact resistance to confirm low-loss current paths. High resistance at breaker contacts can lead to arcing and excessive heat.

Want to model insulation levels across a system? Learn about our Power System Studies

8. Simultaneous Closing and Mechanical Interlocks

Ensure breakers don’t close simultaneously when interlocked. Mechanical interlocks must be tested to prevent parallel feeds and system shorting.

9. Electrical and Mechanical Interlocks

Verify that electrical and mechanical interlocks function correctly—safeguarding against unsafe switching sequences or unauthorized operation.

10. Spring Charging Motor and Limit Switches

Check the spring charging motor and measure charging time. Also verify limit switch behavior, ensuring accurate open/close positioning and signaling.

11. Current Transformers (CTs)

Confirm proper installation and connection of CTs. Accurate current measurement is critical for protection and coordination.

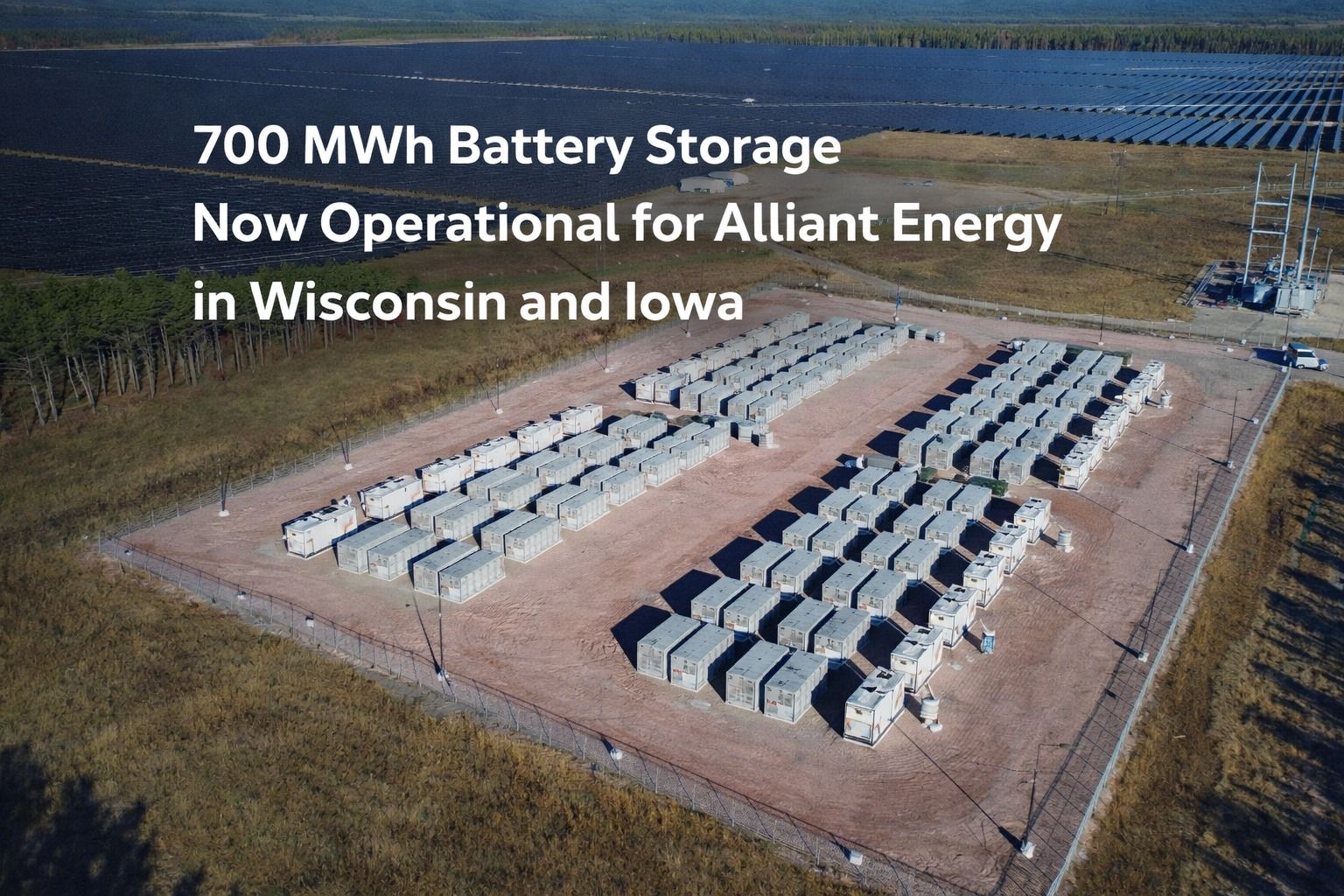

We assist with transformer integration and metering accuracy in our Utility-Scale Battery Storage Services

12. High Voltage Test

Perform a high voltage withstand test to verify insulation integrity under maximum operating voltages. This prevents insulation failure in live conditions.

13. Functional Tests

Conduct comprehensive functional testing, including checks on:

- Auxiliary contacts

- Alarms and signaling

- Local/remote control

- Protection coordination

- Communications (if SCADA integrated)

Conclusion

Commissioning of circuit breakers is not a single-step task—it’s a rigorous, multi-phase process that validates both safety and operational readiness. By performing each step outlined above, engineers ensure compliance, performance, and grid reliability.

Planning NERC-compliant commissioning or protection testing? View our NERC Compliance Services

Trust Keentel for Your Circuit Breaker Commissioning Projects

Keentel Engineering offers professional testing, commissioning, and verification services for medium and high-voltage circuit breakers across utility, BESS, and renewable systems. Whether for new installations or upgrades—we ensure compliance, safety, and performance.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Services

Let's Discuss Your Project

Let's book a call to discuss your electrical engineering project that we can help you with.

About the Author:

Sonny Patel P.E. EC

IEEE Senior Member

In 1995, Sandip (Sonny) R. Patel earned his Electrical Engineering degree from the University of Illinois, specializing in Electrical Engineering . But degrees don’t build legacies—action does. For three decades, he’s been shaping the future of engineering, not just as a licensed Professional Engineer across multiple states (Florida, California, New York, West Virginia, and Minnesota), but as a doer. A builder. A leader. Not just an engineer. A Licensed Electrical Contractor in Florida with an Unlimited EC license. Not just an executive. The founder and CEO of KEENTEL LLC—where expertise meets execution. Three decades. Multiple states. Endless impact.

Leave a Comment

We will get back to you as soon as possible.

Please try again later.