NERC Level 3 Compliance for IBRs — Done Right with Keentel Engineering

Stay ahead of the August 18, 2025 deadline. Ensure your inverter-based resource (IBR) modeling, testing, and documentation are 100% compliant with NERC’s latest alert across ERCOT, PJM, and the broader Bulk Power System.

May 20, 2025 Alert Issued

The Industry is Under Alert — Are You Prepared?

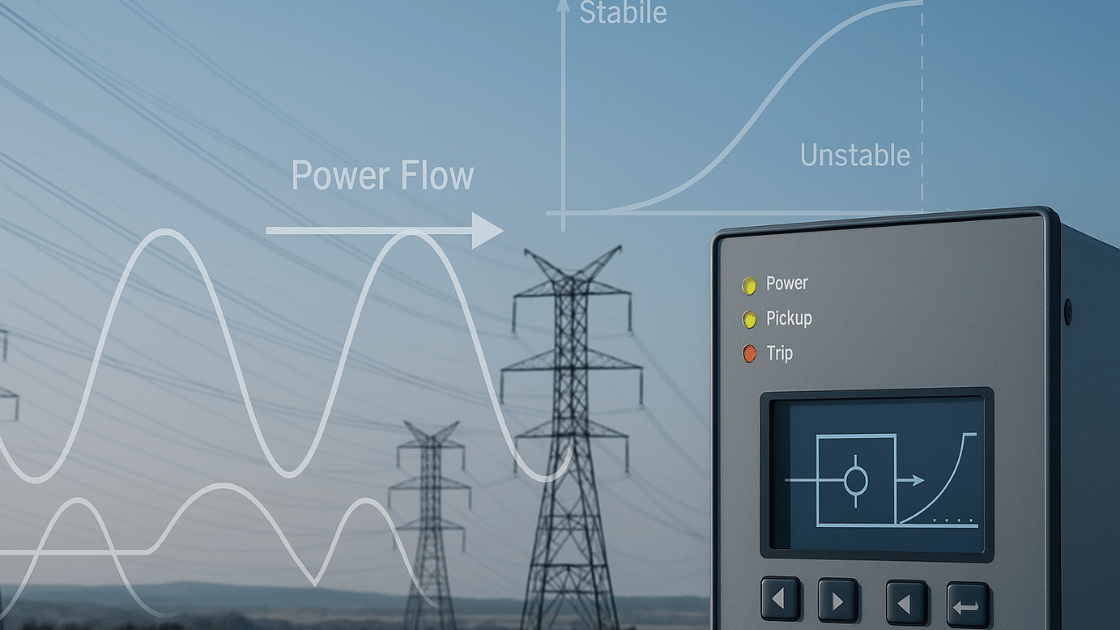

On May 20, 2025, NERC issued its highest-level (Level 3) alert for IBR performance. Generator Owners of solar, wind, storage and other Inverter-Based Resources (IBRs) must validate their equipment models (EMT and PSPD) and performance to prevent grid disruptions. This alert responds to systemic modeling issues that have already led to 15,000+ MW of lost generation on the grid.

These actions are not optional. Failing to respond accurately could result in audit issues, modeling inaccuracies, reputational risks and compromise system reliability.

Request Your Free NERC Compliance Consultation

Contact Keentel for a risk-free consultation. Our experts will review your NERC compliance needs and model readiness in ERCOT, PJM, or any region.

Submit

We will get back to you as soon as possible.

Please try again later.

Why NERC Issued the Level 3 Alert — Industry Impact

Since 2016, over 15,000 MW of generation loss has occurred due to IBR-related issues—unpredictable by current planning models.

The alert demands urgent compliance from Generator Owners (GOs), Transmission Planners (TPs), Transmission Owners (TOs), and Planning Coordinators (PCs). Non-compliance won't incur direct penalties—but can trigger audit flags, FERC scrutiny, and future violations under FAC-001, FAC-002, or related standards.

Learn what actions are required in the NERC Level 3 Alert Compliance Checklist.

What Generator Owners Must Do

Essential actions required by the NERC Level 3 Alert:

Validate Models

Ensure EMT and PSPD models match actual equipment behavior.

Validate Models

Ensure EMT and PSPD models match actual equipment behavior.

Validate Models

Ensure your EMT (electromagnetic transient) and PSPD (positive-sequence phasor domain) models accurately represent your IBR equipment. Obtain OEM-validated models and benchmark them against measured performance.

Conduct Benchmark Tests

Use field and commissioning tests (frequency response, low/high voltage ride-through, etc.) to verify inverter response and align models with real-world behavior.

Track Firmware & Design Changes

Document all equipment settings, control logic, and firmware updates. Update models and notify grid planners (TPs/PCs) whenever inverter parameters change.

Maintain Critical Data

Archive inverter and turbine specifications, control strategies, and configuration files for audits.

Meet the Deadline Alert

Submit all NERC Alert responses via the NERC Alert System by August 18, 2025.

Keentel's NERC Alert Response Services

Keentel Engineering offers end-to-end support for NERC L3 Alert compliance. Our engineering team offers a wide range of services. We are an engineering company with a focus on engineering, procurement, construction and associated regulatory compliance. Our services include:

Compliance Documentation

- Technical write-ups for model settings, control hierarchy, and plant design

- Custom reports for TPs and PCs

- IBR lifecycle information management

Compliance Documentation

Technical reports detailing model settings, control hierarchies, and plant design; custom compliance reports for Transmission Planners (TPs) and Planning Coordinators (PCs); complete IBR data management.

Model Validation & Benchmarking

EMT/PSPD benchmarking reports (using tools like PSSE, TSAT, PSCAD/EMTDC); simulation-vs-field data comparisons; OEM collaboration on model accuracy.

Conformity Assessments

Custom test plans aligned with NERC’s essential actions; field commissioning audits and inverter performance verification.

Change Management Systems

Firmware update tracking, real-time model adjustment support, and audit-trail logs to capture any equipment or model change.

Submission Assistance

Help with NERC Alert acknowledgment, response preparation, and deadline tracking; liaison with TPs and PCs throughout the process.

Get Started — Risk-Free Compliance Assessment

The clock is ticking. Let’s discuss your site’s readiness before NERC does. Schedule a free consultation today to review your IBR models and compliance strategy.

Get Started — Risk-Free Compliance Assessment

The clock is ticking. Let's discuss your site and model readiness before NERC does.

Schedule a Free Consultation Call

Call us directly

813-389-7871

Email us

Your Compliance. Our Commitment.

Keentel Engineering—Your Partner in Power System Integrity and NERC Compliance Services.

🕛 Time Remaining

August 18, 2025

NERC Response Deadline

NERC Level 3 Alert: Urgency, Compliance, and Industry Response

The May 20, 2025 NERC Level 3 Alert isn’t just a guideline—it’s the industry’s most serious compliance action related to inverter-based resources (IBRs). Generator Owners (GOs) are now required to model, test, and validate PSPD and EMT representations with equipment-specific accuracy.

Keentel Engineering provides tailored compliance engineering services that directly respond to this alert, covering every aspect from IBR model validation to documentation submission and change management tracking.

Whether you're working in ERCOT, PJM, or other planning regions, our team ensures your IBR fleet meets the alert requirements and aligns with NERC 693, FAC, and PRC reliability standards. Stay ahead of FERC scrutiny and the August 18 deadline—schedule your free compliance review today.

Why Choose Keentel Engineering?

30+ Years of Grid Compliance and Power Systems Engineering

Proven Track Record in IBR Design, Modeling & Integration

Deep Familiarity with NERC, FAC Standards, and FERC Requirements

Hands-On Support from Validation to Documentation to Submission

Frequently Asked Questions (FAQs)

1. What is the purpose of the NERC Level 3 Alert on IBR Performance and Modeling?

This alert aims to improve modeling accuracy and reliability of Inverter-Based Resources (IBRs) on the Bulk Power System (BPS) by urging GOs, TOs, TPs, and PCs to enhance criteria, policies, and procedures for interconnection, modeling, and performance verification.

➡️ Keentel Service: Regulatory gap analysis and NERC alert compliance planning.

2. Who must comply with the NERC Level 3 Alert?

All registered entities in the roles of GO, TO, TP, or PC are expected to acknowledge and respond. Although not enforceable like Reliability Standards, failure to follow may still lead to reliability risks and scrutiny.

➡️ Keentel Service: Entity-specific action plan development and documentation submission support.

3. Is compliance with this alert mandatory?

No, but it is strongly urged. While it is not a Reliability Standard, entities are expected to implement the Essential Actions to maintain grid reliability.

➡️ Keentel Service: Strategic advisory on voluntary action implementation and future compliance alignment.

4. What is an Inverter-Based Resource (IBR)?

IBRs are energy facilities like solar PV, Type 3/4 wind, BESS, or fuel cells that inject real power via inverters or converters.

➡️ Keentel Service: IBR modeling support and PSSE/TSAT integration for solar, wind, and BESS.

Engineering & Interconnection

5. What are TOs and TPs expected to update in their interconnection requirements?

They must include performance-based criteria for voltage control, frequency response, ride-through capability, post-disturbance behavior, and reactive power support.

➡️ Keentel Service: Development and publication of standardized IBR performance specs.

6. Why is uniform IBR performance necessary?

It ensures predictable behavior across the grid during normal and disturbed conditions, minimizing cascading failures.

➡️ Keentel Service: System studies to verify conformity and recommend tuning.

7. What are the key technical criteria to be defined in interconnection studies?

Interconnection studies for inverter-based resources (IBRs) must clearly define technical performance criteria to ensure compliance with NERC reliability standards and maintain Bulk Power System (BPS) stability. These criteria include voltage control deadbands, frequency droop response limits, low/high voltage and frequency ride-through thresholds, and current priority logic during system constraints. Accurate specification of these parameters is essential for model validation and grid integration.

➡️ Keentel Service: Development of IBR commissioning plans, model validation protocols, and customized interconnection test procedures.

Modeling and Verification

8. What does “model quality” mean in the context of IBRs?

It refers to the fidelity and accuracy of dynamic models (PSPD/EMT) used to represent real-world behavior of IBRs during disturbances.

➡️ Keentel Service: Model validation reports and EMT benchmarking.

9. What documentation should TPs and PCs obtain from GOs?

To comply with the NERC Level 3 Alert for inverter-based resources (IBRs), TPs and PCs must receive key technical documentation from GOs. This includes validated dynamic model reports (EMT or PSPD), parameter mapping summaries, and formal attestations verifying model quality and accuracy. These documents ensure that all interconnected IBRs meet performance expectations and system reliability standards.

➡️ Keentel Service: Full coordination with OEMs and project stakeholders to generate and deliver NERC-compliant documentation packages.

10. How should entities verify that models match as-built performance?

Through field data comparison, performance testing during commissioning, and post-event analysis.

➡️ Keentel Service: Site commissioning supervision and field-model correlation analysis.

11. What is the purpose of performance testing in the modeling process?

To confirm that simulated response of models mirrors real-world operation, enabling reliable planning and protection studies.

➡️ Keentel Service: Development of performance test protocols and automated test reports.

12. Why are EMT models emphasized?

Because they capture high-frequency dynamics and are more accurate for studying fast control responses in modern IBRs.

➡️ Keentel Service: EMT modeling using PSCAD and real-time simulation with HYPERSIM or RTDS.

Change Management & Lifecycle

13. What is required under enhanced change management for GOs?

Tracking and communication of any changes (e.g., firmware, settings, model parameters) to TPs and PCs, ensuring all representations remain accurate.

➡️ Keentel Service: Lifecycle management system design and configuration tracking solutions.

14. What IBR data must GOs retain as part of compliance?

As part of NERC Level 3 Alert compliance for inverter-based resources (IBRs), Generator Owners must retain comprehensive technical data. This includes inverter and plant make/model information, firmware versions, voltage and frequency ride-through curves, plant controller specifications, and protection system settings. Maintaining accurate and accessible records is essential for supporting model validation, performance testing, and future audits.

➡️ Keentel Service: Centralized IBR data repository setup with automated update alerts to support compliance tracking and lifecycle documentation.

15. What’s the importance of tracking firmware updates?

Firmware changes can alter control behavior. If not tracked, they may lead to discrepancies between models and field performance.

➡️ Keentel Service: Firmware tracking and post-upgrade verification protocols.

Reporting & Coordination

16. What are the important deadlines in this alert?

Under the NERC Level 3 Alert for Inverter-Based Resources (IBRs), all Generator Owners must acknowledge receipt of the alert by May 27, 2025, and submit their full compliance response by August 18, 2025 via the NERC Alert System. These deadlines are critical for maintaining Bulk Power System (BPS) reliability and avoiding regulatory scrutiny for non-compliance.

➡️ Keentel Service: End-to-end project management for NERC compliance, including deadline tracking, milestone reporting, and coordination with Transmission Planners (TPs) and Planning Coordinators (PCs).

17. What systems are used for acknowledgment and submission?

The NERC Alert System, which requires acknowledgment, submission, and approval of each response.

➡️ Keentel Service: End-to-end support in navigating the NERC Alert System portal.

Strategic & Future Planning

18. How does this alert connect with future Reliability Standards?

The NERC Level 3 Alert for inverter-based resources (IBRs) directly supports the development of future Reliability Standards by collecting data that will influence updates to FAC-001, FAC-002, and other critical NERC standards. These updates are being shaped in response to FERC Order 901 and aim to strengthen power system planning, interconnection procedures, and IBR performance verification.

➡️ Keentel Service: NERC Reliability Standards alignment consulting and IBR future-readiness strategy development for compliance with evolving FAC and PRC requirements.

19. Why is accurate IBR modeling critical to Bulk Power System (BPS) reliability?

Accurate modeling of inverter-based resources (IBRs) is essential for Bulk Power System (BPS) reliability because transmission planning, protection coordination, and operational stability all rely on precise system models. Inaccurate EMT or PSPD models can lead to misinformed grid responses, resulting in cascading failures or even large-scale blackouts.

➡️ Keentel Service: Comprehensive IBR model validation, benchmarking, and correction services to ensure full NERC Level 3 Alert compliance.

20. How can Keentel Engineering help across the lifecycle of NERC compliance?

From interconnection studies, EMT modeling, and commissioning to change management, Keentel Engineering offers complete IBR lifecycle services tailored to NERC standards.

➡️ Summary of Services:

- PSSE/TSAT/EMT model development

- Performance testing & validation

- NERC Alert reporting assistance

- Change management system setup

- Real-time model tuning

- Regulatory training workshops

Know More About Nerc Alert level 3

21. What is the NERC Severity Risk Index (SRI)?

The SRI is a score that shows how serious power system problems are each day. It adds up how much electricity was lost from transmission, generation, and load issues. The score ranges from 0 to 1000 — higher means more impact on the grid.

22. What are NERC Alerts?

NERC Alerts are official messages sent to power companies to warn them about urgent reliability or modeling issues. These alerts help prevent blackouts and make sure the power grid runs safely.

23. How many NERC standards are there?

NERC has about 100 different rules (called standards) that cover how the power grid should be planned, operated, and protected.

24. What does NERC stand for?

NERC means North American Electric Reliability Corporation. It's a nonprofit group that sets and enforces rules to keep the electric grid safe and reliable across North America.

25. What is a NERC Violation Severity Level (VSL)?

A VSL tells how serious a rule violation is. It’s rated as Low, Moderate, High, or Severe, based on how much risk it causes to the power grid.

26. What are NERC Reliability Standards?

These are rules that power companies must follow to keep the grid running safely and reliably. They focus on performance, safety, and risk management.

27. What does the NERC Alert system do?

The NERC Alert system sends out critical updates and instructions to registered power companies. It helps make sure they’re following the latest safety and reliability rules.

28. What is the difference between Level 2 and Level 3 NERC Alerts?

Level 2 alerts request action with some urgency, but Level 3 alerts—like the May 2025 IBR alert—require immediate attention, coordinated response, and evidence submission. Level 3 is the highest urgency level and often signals system-wide risks.

29. What is meant by “equipment-specific PSPD models”?

These are positive-sequence phasor domain (PSPD) models tailored to each IBR’s design and control characteristics. OEM-validated and field-benchmarked, these models must align with site-specific inverter behavior.

30. How does Keentel support NERC compliance for IBRs in ERCOT and PJM?

Keentel delivers engineering support across major regions, providing PSSE, PSCAD, and TSAT modeling, benchmark testing, firmware audit trails, and alert submission prep specific to ERCOT and PJM compliance protocols.

31. What’s the risk of not submitting by the August 18, 2025 deadline?

Non-submission could trigger red flags during future NERC audits, impact your registration status, and attract scrutiny under FAC-001, FAC-002, or future IBR performance standards. It may also raise your Severity Risk Index (SRI) exposure.

32. Does Keentel help with firmware tracking and model updates?

Yes. We provide full change management system support, including firmware logs, parameter adjustments, and update notifications to TPs/PCs. All updates are recorded with audit-ready trails.

33. Can Keentel handle both modeling and NERC submission?

Absolutely. From IBR benchmarking and conformity testing to RSAW response prep and NERC Alert System submission, we manage the full lifecycle of Level 3 alert compliance.